Para aramid staple fibers for spun yarn and non-woven fabrics.

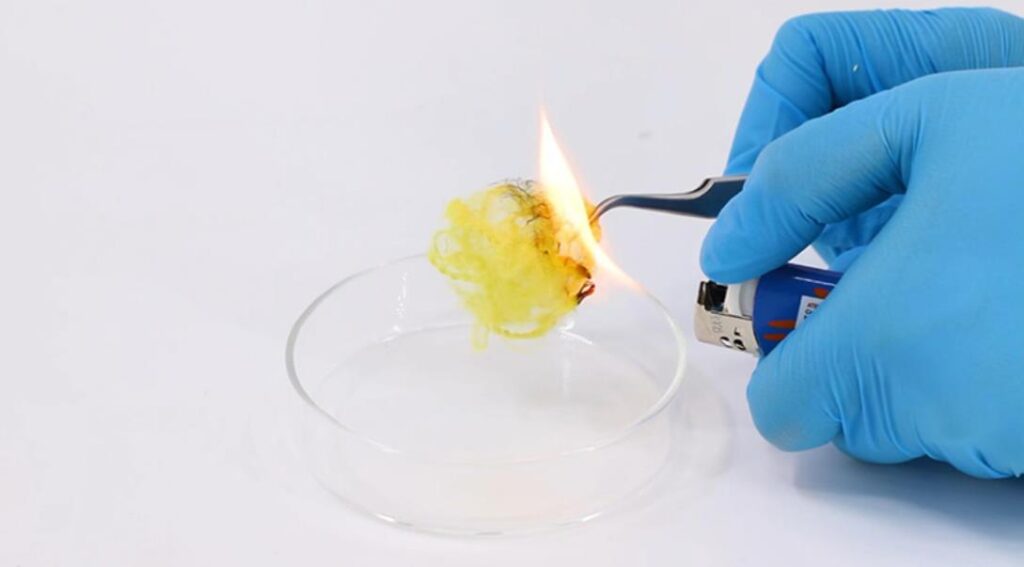

Para-aramid filaments provides extremely high strength and modulus with light weight, also shows excellent flame and abrasion resistance.

para-aramid staple fibers are made from filaments, which are washed, crimped and cut and then treated by surface treatment. With those unique properties both in chemical and physical, staple fiber can perfectly meet all needs from fabric and yarn manufactures to produce protective workwear and variety of other personal protective equipment.

staple fibers are widely used in textile application including high-end yarn, blended yarn, needle-spun felt and non-woven industry. Its essential but multiple linear density and fiber length provide more possibility for softness and comfort.

Features:

- High strength-to-weight ratio

- Heat and chemical resistance

- Flame retardant and fireproofing

- Cut resistance and electricical insulation

Main Applications:

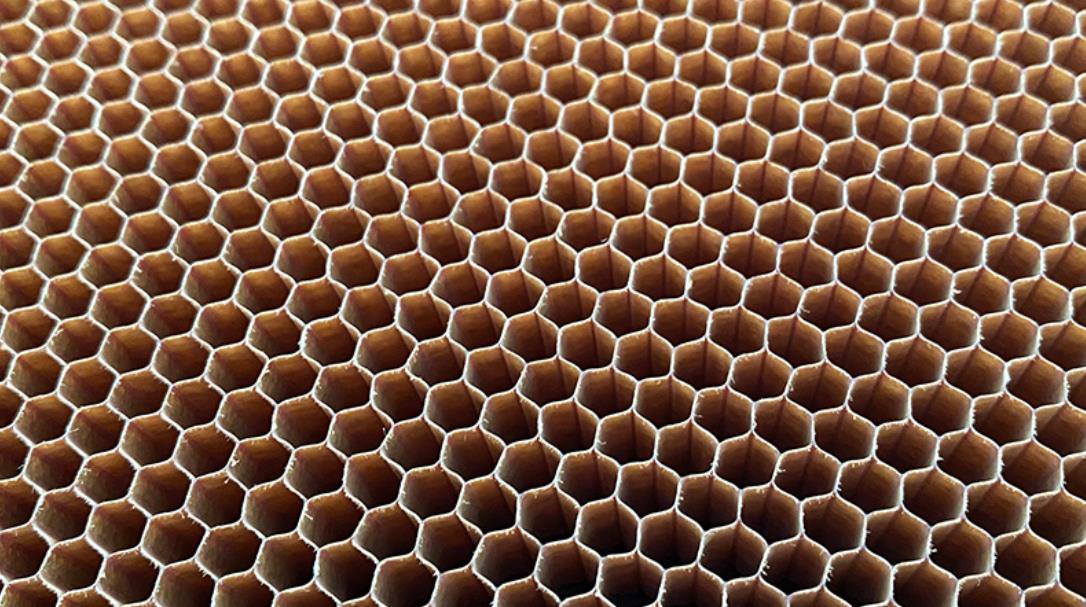

- Thermal insulation

- Filter

- Fabrics, anti-cutting gloves

- Needle-spun felt and non-woven industry

Storage:

para-aramid staple fiber should be kept dry in original bags and properly stocked.

Preferably store at room temperature with 35-65% relative humidity.

Avoid the sun, rain and fire.

Para Aramid Staple Fibers Application:

Packaging:

Net weight:

50 or 100kg per bag

4 bags per pallet