Struggling with materials that are heavy or weak? Para-aramid fiber [1] offers incredible strength without the extra weight. It solves some of the toughest engineering problems you can face.

Para-aramid fiber1 [1] is special because of its very high strength-to-weight ratio2 [2] , heat resistance3 [3] , and durability. It is used in demanding applications like body armor [4] , aerospace parts4 [5] , protective clothing5 [6] , and special cables6 [7] where performance and safety are the most important things.

When I first started in this industry over 15 years ago, I was amazed by this golden-yellow fiber. It looked simple, but it could stop bullets and survive intense heat. It seemed like something from the future. But it's not just about its basic properties. The real magic is in how we can customize it for very specific jobs. It's a versatile material that goes far beyond its standard form. Let's look at some of the special versions we work with and how they solve unique challenges for our customers.

Can You Get Para-Aramid in Different Colors for Special Designs?

Are you tired of the standard yellow color limiting your product design? You need a material that is both strong and visually appealing. Solution-dyed para-aramid offers vibrant, lasting color.

Yes, you can get para-aramid in different colors through a process called solution dyeing. This method mixes the color directly into the fiber as it's being made. The result is excellent color fastness7 [8] , making it perfect for products like custom phone cases or branded protective gear.

Most people know para-aramid for its natural golden-yellow color. But what if you need a different look? This is a common question I get from clients, especially those in consumer products. For example, a company making high-end phone cases wanted to use para-aramid for its strength but needed it in black to match their brand. The answer is solution dyeing. This process is very different from just dipping the final fiber in dye. We add the color pigment during the fiber's creation. This locks the color deep inside the fiber itself. As a result, the color won't fade, peel, or wash out, even under harsh conditions. This is what we call superior color fastness [8] . It’s a game-changer for applications where both performance and appearance matter.

Why Solution Dyeing is Better

The traditional way to color fabric is piece dyeing, where you dye the finished product. This is not very effective for para-aramid because the fiber is so dense and resistant to chemicals. Solution dyeing solves this problem.

| Feature | Solution Dyeing | Traditional Piece Dyeing |

|---|---|---|

| Color Location | Inside the fiber | On the surface of the fiber |

| Color Fastness | Excellent, will not fade | Poor, can rub or wash off |

| Best For | High-performance gear, phone cases | Cotton shirts, less demanding uses |

| Process | Pigment added before fiber is spun | Finished fiber is dipped in dye |

This makes solution-dyed para-aramid8 [9] the only real choice for products that need to look good for a long time.

What Does Fine Denier Para-Aramid Mean for High-Tech Industries?

Do you work with delicate, high-tech components? Standard fibers might be too thick and clunky for your needs. Fine denier para-aramid9 [10] provides the same strength in a much thinner form.

Fine denier para-aramid [10] refers to extremely thin fibers. This is crucial for high-tech industries like advanced medical equipment. For example, it is used to reinforce tiny optical cables10 [11] , providing strength without adding bulk. Producing it shows a factory has very advanced manufacturing capabilities.

When we talk about fibers, "denier" is a unit of measurement for its thickness. A lower denier means a finer, thinner fiber. For reference, a single strand of silk is about 1 denier. Many factories can produce standard para-aramid, maybe around 1000 or 1500 denier. But producing very fine deniers, like 200 or 400, is much harder. It requires precise control over the entire production process, from the chemical mixture to the spinning machines. I remember a client from the high-end medical industry who needed to reinforce a new type of fiber optic cable for surgical tools. The cable had to be incredibly thin and flexible but also strong enough to withstand handling. Standard para-aramid was too bulky. Our fine denier fiber was the perfect solution. It provided the necessary strength without compromising the cable's size or flexibility.

Understanding Denier and Its Impact

Producing fine denier fiber is a sign of a manufacturer's technical skill. The process is sensitive and requires top-tier equipment and expertise.

| Denier Grade | Typical Application | Manufacturing Difficulty |

|---|---|---|

| Standard (1000D+) | Ropes, tires, |

body armor [4] | Standard | | Medium (400D - 800D) | Hoses, composites, protective gloves | High | | Fine (Under 400D) | Medical optical cables [11] , specialty fabrics | Very High |

This ability to produce fine denier fiber opens doors to cutting-edge applications. It shows we can meet the demands of the most innovative industries in the world.

Is It Possible to Add Special Coatings to Para-Aramid Fibers?

Does your project have unique requirements that standard fibers can't meet? You might need conductivity or other special properties. Applying a surface coating to para-aramid can unlock new functions.

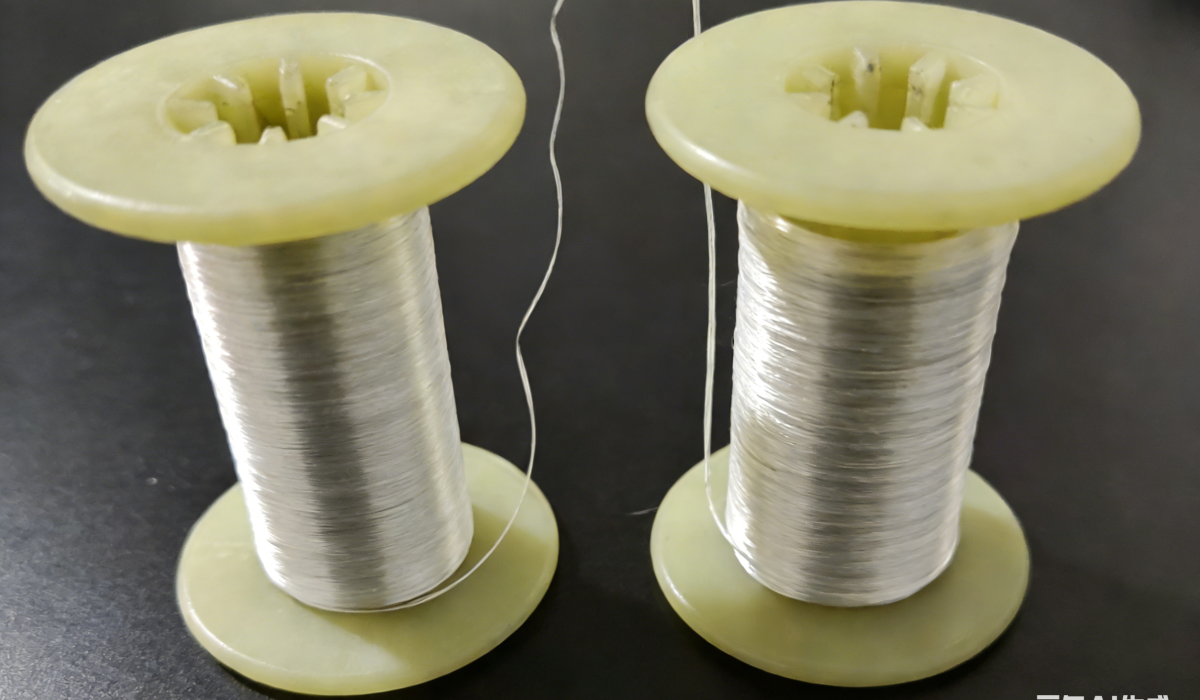

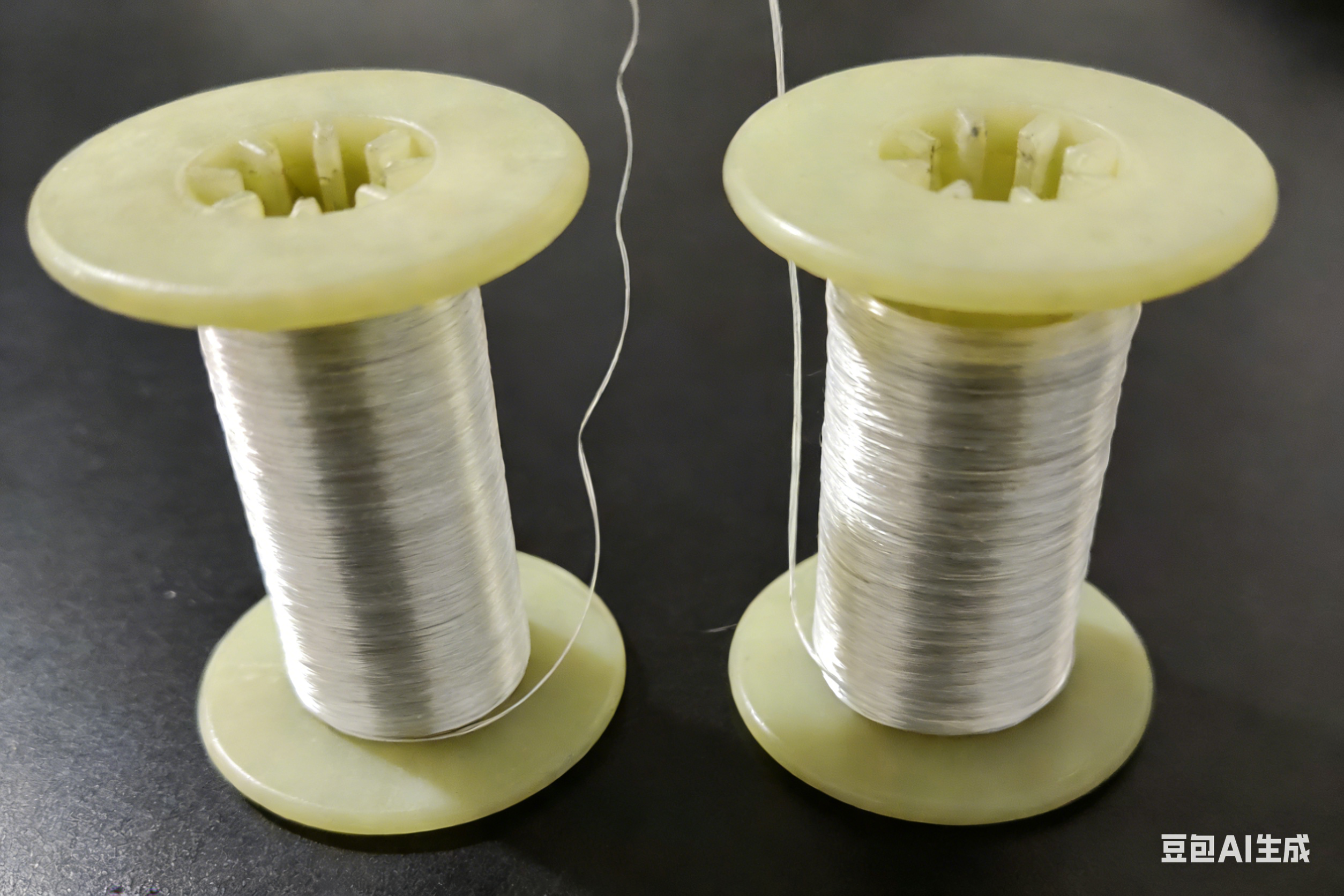

Yes, special coatings11 [12] can be applied to para-aramid fibers to give them new properties. For example, a silver coating can make the fiber electrically conductive. This is used in special military applications and smart textiles12 [13] where advanced material performance is required.

Para-aramid is already an amazing material. But sometimes, a project needs more. It might need to conduct electricity, resist static, or have antimicrobial properties. This is where surface coatings come in. We can take the finished para-aramid fiber and apply a very thin layer of another material to its surface. One of the most interesting requests I've ever had was from a client working on a defense project. They needed a fabric that was not only strong and cut-resistant but also had specific electronic properties. We worked with them to develop a silver-coated para-aramid [14] fiber. The para-aramid provided the core strength, while the silver coating added the necessary conductivity. This process is highly specialized. It requires careful preparation of the fiber to ensure the coating sticks properly and is evenly applied.

How Coatings Enhance Fiber Performance

Coatings are not just for looks; they add real functionality. The process transforms a standard strong fiber into a multi-functional smart material.

- Conductivity13 [15] : Silver or copper coatings can be used to create conductive yarns for smart textiles12 [13] or for shielding against electromagnetic interference (EMI).

- Adhesion: Some coatings, often called a "finish," are applied to help the fiber bond better with resins in composite materials. This makes the final part stronger.

- Other Properties: We can explore coatings that add UV resistance, antimicrobial effects, or even different colors if solution dyeing is not an option.

This ability to customize the fiber at a surface level means we can engineer solutions for very specific and complex problems. It takes a great material and makes it even better.

Why Do High-Strength and High-Modulus Para-Aramids Matter So Much?

Are the standard materials you use failing under high stress or stretching too much? You need a material that can handle extreme loads without deforming. High-strength and high-modulus para-aramids are the answer.

High-strength para-aramid14 [16] can withstand greater force, making it ideal for ballistic protection like body armor [4] . High-modulus para-aramid15 [17] resists stretching, which is critical for things like special optical cables10 [11] that need to maintain their length and integrity. Producing these grades shows superior manufacturing control.

Not all para-aramid is created equal. While all of it is strong, we can fine-tune the production process to create different grades. The two most important advanced grades16 are high-strength and high-modulus. "Strength" refers to how much force a fiber can take before it breaks. "Modulus" refers to how much the fiber resists stretching when you pull on it. Many manufacturers can produce a standard grade. But producing a high-strength, bulletproof-grade fiber requires incredible precision. The same goes for high-modulus fibers. I have worked with companies making optical cables10 [11] for deep-sea use. They need the fiber to protect the delicate glass inside, but it absolutely cannot stretch, as that would damage the optical core. Our high-modulus para-aramid was the only thing that worked for them.

Comparing Different Para-Aramid Grades

The ability to produce these specialized grades is a key indicator of a factory's quality and technical expertise. It's the difference between making a good product and making a world-class one.

| Grade | Key Property | Primary Use Case | Why It's Special |

|---|---|---|---|

| Standard | Good all-around balance | Ropes, hoses, general reinforcement | The baseline for para-aramid performance |

| High-Strength | Resists breaking under force | Body armor, helmets, |

ballistic panels17 [18] | Maximizes energy absorption and impact resistance | | High-Modulus | Resists stretching (stiffness) | Optical cables, high-performance sails | Ensures dimensional stability18 [19] under tension |

Being able to offer these different grades means we can provide the exact right material for the job, whether it's protecting a life or ensuring a data signal travels thousands of miles.

Conclusion

Para-aramid is more than just a strong yellow fiber. Its true value lies in its versatility19, from custom colors to advanced grades16 for the most demanding applications in the world.

Explore how Para-aramid fiber is used in various industries for its strength and durability, offering solutions to engineering challenges. ↩

Learn why materials with a high strength-to-weight ratio are crucial for applications requiring both durability and lightness. ↩

Understand the importance of heat resistance in materials, especially for applications exposed to high temperatures. ↩

Find out how Para-aramid fiber contributes to the aerospace industry by offering lightweight and durable solutions. ↩

Explore the benefits of using Para-aramid fiber in protective clothing, ensuring safety and comfort for users. ↩

Learn how Para-aramid fiber enhances the performance and durability of special cables used in demanding environments. ↩

Understand the significance of color fastness in solution-dyed Para-aramid fiber for long-lasting and vibrant product designs. ↩

Discover the advantages of solution dyeing for Para-aramid fiber, offering customization in color without compromising strength. ↩

Explore how fine denier Para-aramid fiber is used in high-tech industries for delicate yet strong components. ↩

Learn how Para-aramid fiber reinforces optical cables, providing strength without adding bulk. ↩

Discover how special coatings enhance the functionality of Para-aramid fibers, adding properties like conductivity. ↩

Find out how Para-aramid fibers contribute to smart textiles, offering advanced material performance. ↩

Explore the role of conductivity in Para-aramid fibers, enabling applications in electronics and smart textiles. ↩

Learn about the advantages of high-strength Para-aramid fiber in applications requiring maximum force resistance. ↩

Understand the importance of high-modulus Para-aramid fiber in applications needing dimensional stability under tension. ↩

Discover the different advanced grades of Para-aramid fiber, tailored for specific high-performance applications. ↩

Discover how Para-aramid fibers improve the effectiveness of ballistic panels, providing superior impact resistance. ↩

Learn about the significance of dimensional stability in Para-aramid fibers for maintaining integrity under stress. ↩

Explore the versatility of Para-aramid fiber, from custom colors to advanced grades for various demanding uses. ↩