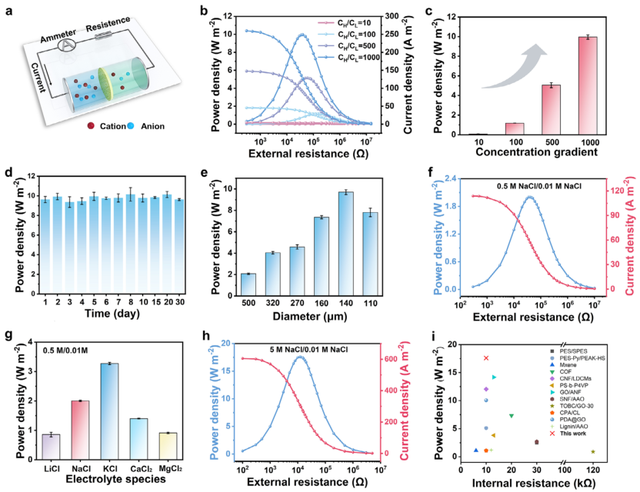

Meta Description: Breakthrough research from Wuhan Textile University transforms waste aramid fabric into aerogel fibers for self-powered sensors. Achieves 17.6 W/m² power density & 0.2 mN force detection for wearable tech and IoT.

Keywords: Self-Powered Sensor, Tactile Sensing, Aerogel Fiber, Aramid Nanofiber, Energy Harvesting, Osmotic Power, Wearable Technology, Flexible Electronics, IoT Sensors, Waste Recycling

A research team led by Professor Wang Jinfeng and Dr. Zhang Shouwei at Wuhan Textile University has developed a groundbreaking method to convert waste aramid fabric into advanced aerogel fibers. This innovation paves the way for high-sensitivity, self-powered tactile sensors and efficient osmotic energy conversion, with significant implications for wearable technology and the Internet of Things (IoT).

The Challenge: Overcoming Limitations of Traditional Materials

While bio-inspired nano-porous membranes show promise for sensing and energy harvesting, their traditional 2D forms often suffer from poor mechanical strength, instability, and difficulties in large-scale production. Although fibrous materials offer flexibility, the high internal resistance of nanoscale channels limits their power output and sensing sensitivity. Maintaining the structural integrity of aerogel fibers in aqueous environments has also been a major hurdle.

The Solution: Sustainable Aerogel Fibers from Waste

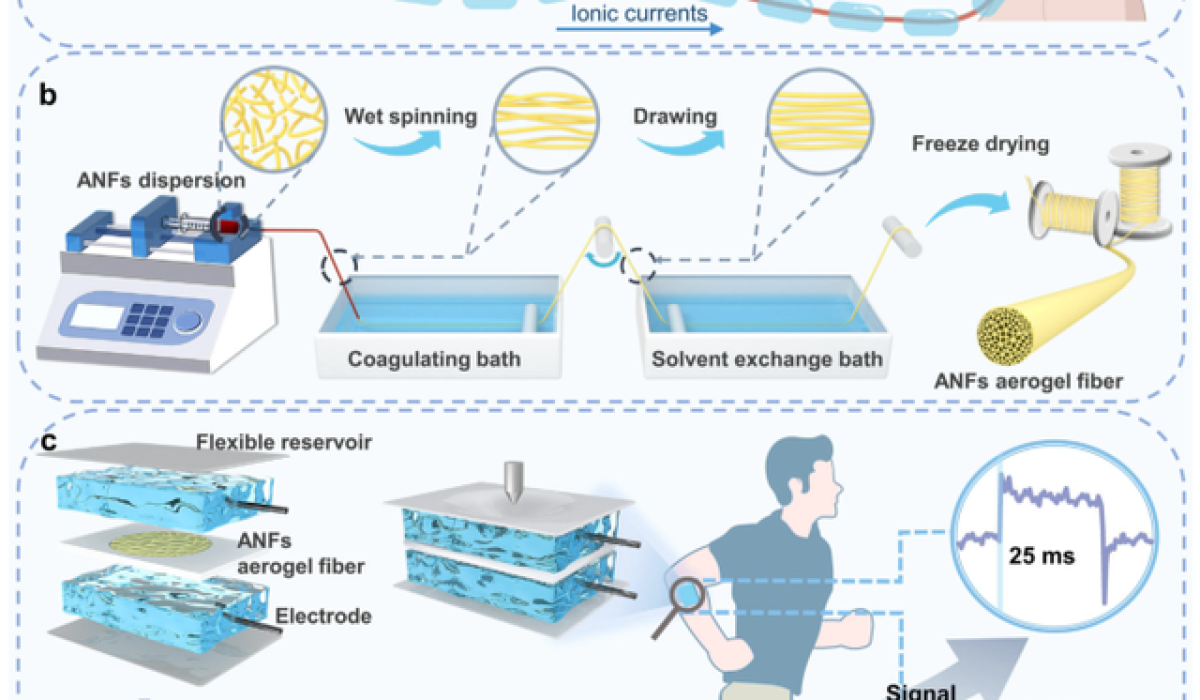

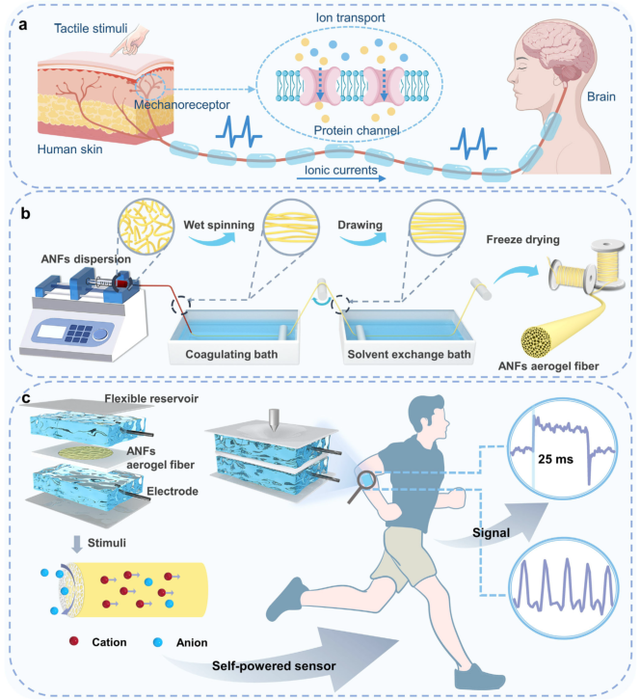

The team successfully addressed these challenges using a sustainable approach. Through a process of wet-spinning and freeze-drying, they transformed discarded aramid textiles into uniform aramid nanofiber (ANF) aerogel fibers with a stable 3D nanoporous structure.

Key Material Properties:

- Source Material: Recycled waste aramid fabric.

- Structure: Robust 3D nanoporous network formed by hydrogen bonding.

- Surface Chemistry: Negatively charged (-COOH groups), enabling cation-selective transport.

- Mechanical Properties: Excellent flexibility and strength, capable of withstanding knotting and twisting.

Breakthrough Performance Metrics

The ANF aerogel fibers demonstrated exceptional performance in two key areas:

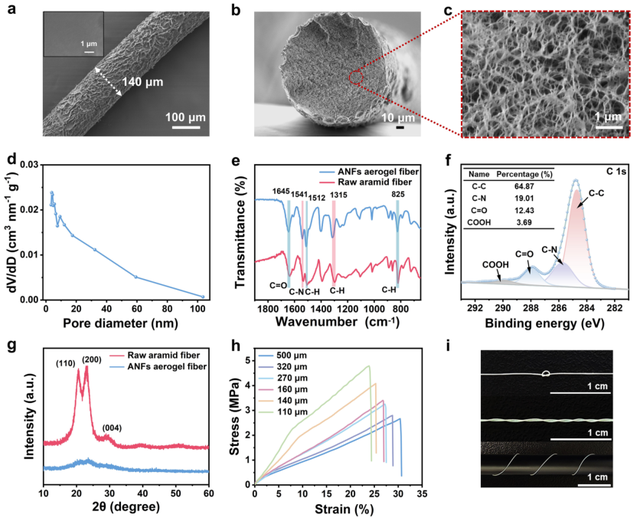

1. Osmotic Energy Harvesting:

- Ultra-Low Internal Resistance: Approximately 10 kΩ, which is significantly lower than most nanofluidic materials.

- High Power Density: A maximum output of 17.6 W/m² under a 500-fold NaCl concentration gradient.

- Long-Term Stability: Stable performance over extended periods (tested for 3600 seconds).

2. Self-Powered Tactile Sensing (Biomimetic Skin):

- High Sensitivity: Can detect ultralow forces as small as 0.2 mN.

- Fast Response Time: An incredibly quick reaction of 25 milliseconds.

- Excellent Stability: Reliable and repeatable signal generation under rhythmic pressure.

- Application Demonstrated: Real-time motion monitoring (e.g., finger bending) and communication via Morse code (“SOS,” “HELP”).

How It Works: The Biomimetic Principle

The sensor mimics the tactile sensing mechanism of human skin.

- A single ANF aerogel fiber is encapsulated in a polymer like Polydimethylsiloxane (PDMS) and immersed in a saline solution.

- Under pressure, the fiber deforms, selectively driving cations (e.g., K⁺) through its negatively charged nanochannels.

- This creates a measurable ionic current signal proportional to the applied force, eliminating the need for an external power source.

Applications and Future Outlook

This technology holds immense potential for:

- Next-Generation Wearable Electronics: For continuous health monitoring (heart rate, joint movement) without batteries.

- Advanced Robotic Skin: Providing robots with highly sensitive touch perception.

- Human-Machine Interfaces: Creating more intuitive control systems.

- Sustainable Power Generation: Harvesting “blue energy” from salinity gradients (e.g., where river meets sea).