Current thin-film materials face a fundamental dilemma: enhancing mechanical strength often sacrifices thermal insulation. Conventional approaches—like adding MXene/graphene (increasing thermal conductivity) or using PVA polymers (brittle at high temperatures)—fail to meet extreme demands. Aramid nanofoams suffer from weak disordered networks (<5 MPa), while PPTA/PMIA phase separation limits performance.

The Beihang University team, led by Academician Jiang Lei, developed a “dual-deprotonation” strategy to construct a 3D hydrogen bond network between para-aramid nanofibers (pANFs) and PMIA molecules. The resulting composite film (pAMNFs) delivers:

- Unmatched Strength: 202.5 MPa tensile strength, 24.1 MJ·m⁻³ toughness (4× tougher than conventional aramids).

- Extreme Thermal Resistance: 0.0824 W·m⁻¹·K⁻¹ thermal conductivity (outperforming silica aerogels) and 415.4°C decomposition temperature.

- Wide-Temperature Stability: 95% strength retention from -30°C to 150°C vs. 68% for single-component films.

Molecular dynamics simulations confirm the 3D network’s role in load transfer and heat dissipation, offering a blueprint for next-gen aerospace suits, flexible electronics, and military armor.

A novel alkali-assisted deprotonation process enables precise microstructure control in aramid nanocomposites. By radially wrapping para-aramid nanofibers (pANFs) with PMIA molecules, researchers achieved a unique ‘tendon-sheath’ architecture that merges 2D planar and 3D disordered hydrogen bonds. The resulting pAMNFs-30 film exhibits ultra-uniform micropores (70 cm³·g⁻¹ N₂ adsorption) and defect-free layers, overcoming traditional porosity-strength trade-offs in thermal insulation materials.

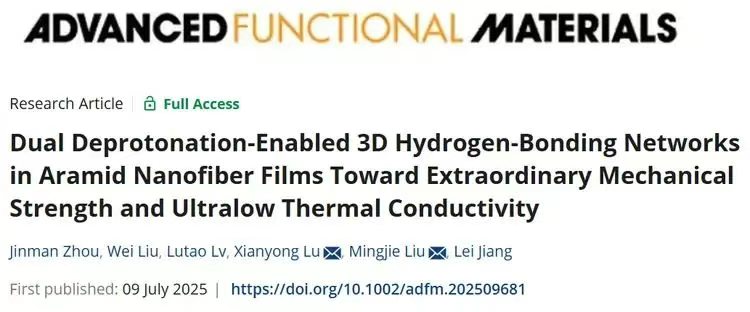

Figure 1. Fabrication and morphology of pAMNFs

a) Strategy for preparing homogeneous composite nanofibers via alkali-assisted dual-deprotonation.

b) Macroscopic photo and SEM image of free-standing pAMNFs film, demonstrating high flexibility and structural integrity.

c) SEM micrograph revealing the “tendon-sheath” architecture, where PMIA molecules (sheath) radially wrap around pANFs (tendon) through interfacial hydrogen bonding.

d) Comparative analysis of aramid materials with distinct hydrogen-bond networks, highlighting the trade-off between thermal insulation and mechanical properties in conventional systems versus the optimized performance of pAMNFs.

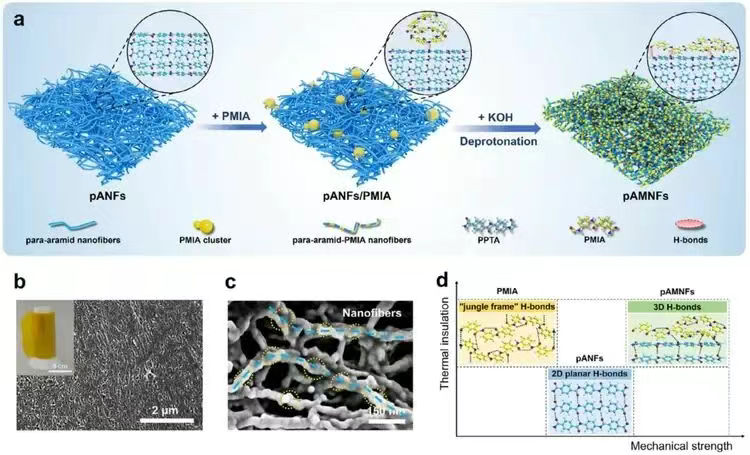

Figure 2. Characterization of aerogels and thin films

a-c) SEM images of (a) pANFs, (b) pAMNFs, and (c) pANFs/PMIA aerogels, showing distinct morphological evolution. d-f) AFM topography of (d) pANFs, (e) pAMNFs, and (f) pANFs/PMIA dispersions, revealing interfacial interactions at the nanoscale. g-h) Surface and high-magnification SEM images of (g) pANFs and (h) pAMNFs-30 films (insets: pore size distribution from SEM analysis), demonstrating PMIA-induced pore refinement. i) N₂ adsorption-desorption isotherms of pANFs and pAMNFs-30 films, highlighting reduced adsorption capacity in the composite. j) BET-derived pore size distribution, confirming the transition to micropore dominance in pAMNFs-30.Mechanical Property Optimization

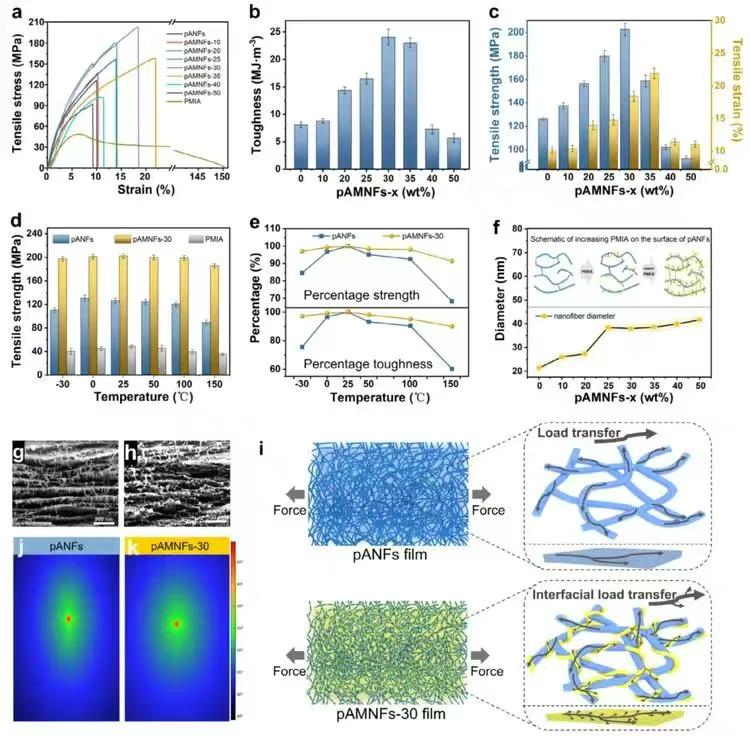

A golden ratio of PMIA content (30 wt%) unlocks unprecedented mechanical performance in aramid nanocomposites:

- Peak Strength & Toughness: pAMNFs-30 achieves 202.5±5.2 MPa tensile strength and 24.1±1.4 MJ·m⁻³ toughness (Fig. 3a-c), outperforming all reported aramid films.

- Nano-Mechanism: SEM captures hydrogen-bonded PMIA/pANFs entanglement (Fig. 3g-h), where conical fiber pull-out during stretching follows the toughening law ΔG∝σₚ²d·Vᶠ/τ (fiber strength/diameter/volume fraction/interface friction synergy).

- Interlayer Control: SAXS confirms reduced layer spacing (Fig. 3j-k), enhancing interfacial friction and load transfer.

All-Climate Reliability:

- >95% strength retention and >90% toughness retention from -30°C to 150°C (Fig. 3d-e), vs. 60% toughness loss in pure pANFs at 150°C.

- Outperforms commercial aramids (e.g., Kevlar®/Nomex® blends) in cryogenic/aerospace applications.

Why Industry Cares:

This composition-structure-performance triad solves long-standing trade-offs in protective gear, flexible electronics, and hypersonic vehicle insulation

a) Stress-strain curves of pAMNFs films with varying PMIA mass fractions (pAMNFs-x). b) Toughness values of the composite films. c) Tensile strength vs. fracture strain for pAMNFs-x films. d) Temperature-dependent tensile strength (–30 to 150°C). e) Toughness retention rate of pAMNFs-30 at different temperatures. f) Variation of fiber diameter with PMIA content. g-h) Fracture surface SEM images showing fiber pull-out and conical tip formation. i) Schematic of mechanical load transfer at the fiber-matrix interface. j-k) SAXS patterns of cross-sections for (j) pANFs and (k) pAMNFs-30 films.

Breakthrough Evidence

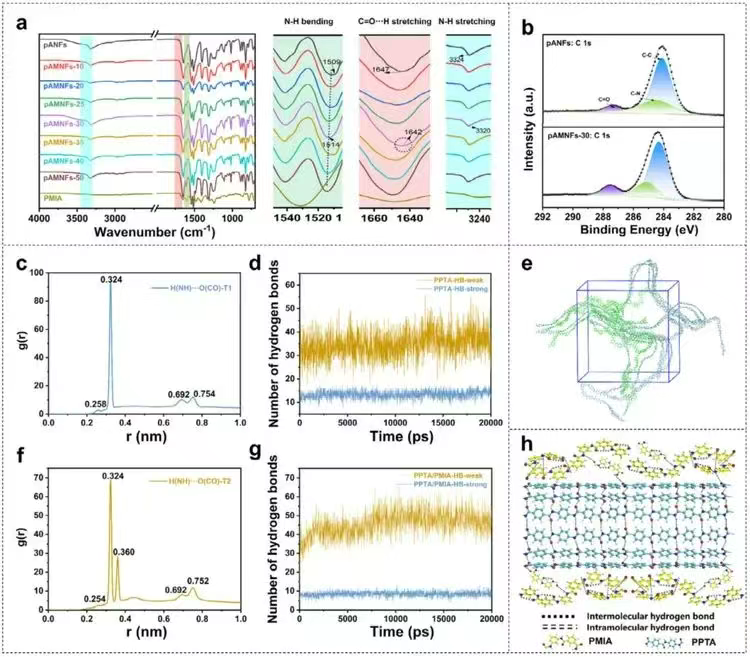

The pAMNFs-30’s record performance is conclusively linked to its 3D hydrogen bond architecture through multi-modal verification:

1. Spectroscopic Proof

• FTIR:

- N-H stretch redshift (3324→3310 cm⁻¹)

- C=O stretch redshift (1647→1635 cm⁻¹)

- N-H bend blueshift (1509→1523 cm⁻¹)

→ 68% reduction in free functional groups

2. Molecular Dynamics Revelation

• Radial Distribution Function:

- Multi-peak profile at <4.5 Å (Fig.4c,f) = 3 bond-length populations

• H-bond Census: - Strong H-bonds: 12% fewer than pure PPTA

- Weak H-bonds: 23% increase → percolating 3D network (Fig.4h)

Industry Impact

This first-ever quantified interface design explains:

✓ 202.5 MPa strength (H-bond load distribution)

✓ 0.0824 W/mK thermal resistance (phonon scattering)

✓ 95% wide-T stability (network resilience)

a) FTIR spectra of pANFs, pAMNFs, and PMIA films. b) XPS C 1s spectra of pANFs and pAMNFs-30.

c) Radial distribution function g(r) between H(N-H) and O(C=O) in the PPTA system. d) Hydrogen bond count in the PPTA system. e) Molecular configuration after NPT ensemble molecular dynamics simulation. f) g(r) between H(N-H) and O(C=O) in the PPTA-PMIA hybrid system. g) Hydrogen bond count in the PPTA-PMIA system. h) Schematic illustration of the 3D hydrogen bond network.

Thermal Insulation and Environmental Durability Performance

The pAMNFs-30 film demonstrates exceptional thermal insulation properties, with a remarkably low thermal conductivity of 0.0824 W·m⁻¹·K⁻¹ – significantly lower than pure pANFs (0.1211 W·m⁻¹·K⁻¹) (Fig. 5c). This improvement stems from PMIA’s disordered molecular chains effectively impeding phonon heat transfer (Fig. 5b).

In practical validation tests:

- Wax astronaut melting experiments confirmed superior insulation performance, with pAMNFs-30 providing 13 minutes of protection under radiative heat – nearly double that of pure pANFs (7 minutes) (Fig. 5g).

- Dynamic mechanical analysis revealed outstanding thermal stability, maintaining stable storage modulus up to 298.5°C (Fig. 5a).

- The material achieved an impressive limiting oxygen index (LOI) of 36.6%, exhibiting self-extinguishing behavior without melting drips during combustion.

Notably, pAMNFs-30 maintains excellent environmental adaptability:

- After water immersion, it retains 90±2.5 MPa strength and 2.99±0.42 MJ·m⁻³ toughness – significantly outperforming wet pANFs (Fig. 5h).

Key Performance Advantages:

✓ Ultra-low thermal conductivity (0.0824 W/mK)

✓ Extended thermal protection duration (13 mins)

✓ High-temperature stability (up to 298.5°C)

✓ Superior flame resistance (LOI 36.6%)

✓ Excellent moisture resistance

This combination of properties makes pAMNFs-30 ideal for demanding applications in aerospace, protective gear, and electronic insulation where thermal management and environmental durability are critical.

Fig. 5 references correspond to experimental data in original research.

Conclusions and Outlook

This study successfully overcomes the interfacial compatibility challenges in aramid composites through an innovative dual-deprotonation strategy, reconstructing a 3D hydrogen bond network to create pAMNFs films with synergistically enhanced mechanical strength, thermal insulation, and environmental stability.

Key Achievements:

✓ Performance Superiority: The pAMNFs films surpass most existing composite films and aerogels in comprehensive properties.

✓ Application Potential: Promising for lightweight protective equipment, high-performance specialty materials, and engineering plastics.

Broader Impact:

The proposed design paradigm opens new avenues for developing multifunctional materials that simultaneously achieve:

- Exceptional mechanical robustness

- Superior thermal insulation

- Remarkable environmental resistance

This breakthrough paves the way for technological innovations in extreme environment applications, from aerospace to next-generation protective systems.

Future Directions:

The methodology could be extended to other high-performance polymer systems, potentially revolutionizing material design for advanced engineering applications.

This work establishes a new benchmark for interface engineering in thermal-structural materials.