Body armor, also known as bulletproof vest, is an important part of individual soldier protection. It consists of two parts: bulletproof layer and coat. The bulletproof mechanism of clothing to warhead and explosive fragments is all different.1.1 Hard body armor.

The bulletproof layer of hard body armor is made of metal materials such as special steel plates and super aluminum plates, or non-metallic materials such as alumina and silicon carbide, similar to ancient breastplates, as shown in Figure 1. The bulletproof mechanism of hard body armor is to deform and break the projectile itself through the destruction of the bulletproof material to a certain extent, so as to absorb kinetic energy and prevent penetration. Although the hard body armor has a certain bulletproof performance, it is easy to produce secondary fragments and cause harm to the human body. Its equipment is heavy, stiff, poor in comfort, and the wearer has poor mobility.

1.2 Soft body armor

Body armor made of soft bulletproof materials has good flexibility, can be worn close to the body, and has good concealment, which has become a research hotspot in recent years. The bulletproof mechanism of soft bulletproof materials is to use the stretching, fracture and friction of multi-layer fabrics to absorb and consume the kinetic energy of bullets or fragments to intercept them. Soft bulletproof vests are mostly inner-wearing bulletproof vests with strong concealment, as shown in PIC 2

1.3 Composite body armor Composite bulletproof vest is a hard bulletproof plate installed inside the soft bulletproof vest, also known as semi-rigid and semi-soft bulletproof vest. Due to the high quality and high hardness of the bulletproof plate, it is larger than the soft body armor, and the wearing flexibility, comfort and mobility are reduced. But from the perspective of defense capability, the bulletproof of composite body armor has been greatly improved. Its mechanism is to integrate the two protective mechanisms of hard body armor and soft body armor, which is suitable for high-risk occasions. When attacked by a gun, the bullet will first enter the first line of defense in the composite body armor, that is, it will contact the bulletproof insert made of ceramic or high-performance fiber material laminates, and the bullet and the bulletproof insert will appear at the moment of contact. cracks and absorbs most of the energy. As the second line of defense, the soft bulletproof material will absorb and diffuse the energy of the remaining part of the bullet and act as a buffer, thereby improving the protection effect. As shown in Figure 3, it is a composite bulletproof vest, which can be equipped with a hard bulletproof plate to improve the protection level.

2 Fibers and materials for body armor the body armor is composed of two parts, the bulletproof layer and the coat, and the material used in the bulletproof layer is the primary factor for the body armor to reduce weight and improve wearing comfort. Bulletproof materials have developed from original steel plates and aluminum alloys to bulletproof nylon plus aluminum sheets or ceramic sheets, and then to high-strength nylon fibers and aramid fibers, ultra-high molecular weight polyethylene fibers and shear thickening liquid bulletproof materials. Big breakthrough.

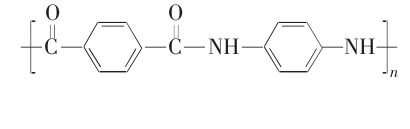

2.1 Aramid fiber 2.1.1 Aramid II fiber Aramid II fiber belongs to aromatic polyamide fiber, commonly known as aramid 1414 fiber and para-aramid fiber. The resulting organic polymer synthetic material has a molecular structure as shown in Figure 4.

Aramid II fiber has super thermal stability, high strength and high modulus, wear resistance, impact resistance and other characteristics, and is an organic fiber with excellent comprehensive performance so far. In addition to high-strength and high-modulus tensile properties, it also has the characteristics of high temperature resistance, flame retardancy, insulation and chemical corrosion resistance. Its impact resistance is 1.6 times that of nylon and 2.0 times that of steel; its specific strength is 6.0 times that of steel wire; The specific modulus is 3.0 times that of steel wire and 2.0 times that of high-strength nylon; the impact resistance is 10.0 times that of polyester industrial yarn. It can still maintain a high level in the temperature range of -200 ~ 200 ℃, and is widely used in military and civilian fields.

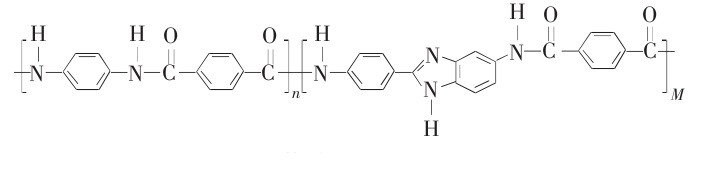

2.1.2 Aramid III fiber Aramid III fiber refers to three-way low-temperature co-condensation of p-phenylenediamine (PPDA), benzimidazole heterocyclic diamine (DAPBI) and terephthaloyl chloride (TPC) in an amide-salt solvent system. Polymerized spinning solution is formed, and the aramid fiber containing heterocyclic structure is obtained through spinning, post-treatment and other processes, and its molecular structure is shown in Figure 5.

Compared with aramid fiber II, due to the introduction of benzimidazole heterocyclic structure, the mechanical properties of aramid fiber III are improved by about 30%. At the same time, the introduction of heterocyclic structure improves the interfacial properties of the fiber, which is more conducive to compounding. Domestic enterprises that have formed large-scale production of aramid fiber III include Inner Mongolia Synthetic Chemical Research Institute, Zhonglan Chenguang Chemical Research and Design Institute, Sichuan Phaeton Technology Co., Ltd., etc. The bulletproof chip of the aramid III “Jinchanjia” body armor developed by the First Research Institute of the Ministry of Public Security is made of domestic aramid III material, which is made of UD non-weft fabric through a specific resin system and unique processing technology. The product has reached the standard of GA141-2010 “Police Body Armor”. Compared with aramid II body armor with the same protection level, aramid III “Jinchanjia” body armor has obvious advantages in terms of weight reduction effect and lightness.

2.2 Ultra-high molecular weight polyethylene The English name of ultra-high molecular weight polyethylene is abbreviated as UHMWPE (hereinafter referred to as PE). PE fiber has the characteristics of low density, high strength, high modulus, wear resistance, and corrosion resistance. Its impact resistance and specific energy absorption capacity are both higher than Para-aramid is nearly 1.0 times higher, and its specific impact load is 10.0 times that of steel and more than 2.0 times that of aramid. Therefore, PE fiber has become a high-quality material for making bulletproof vests, bulletproof helmets, stab-proof clothing and shields. At present, the density of PE fiber is 0.97g/cm³, the tensile breaking strength and modulus can reach 3.2~4.0GPa and 100.0~140.0GPa respectively, and the breaking elongation is 3.7%~4.5%.

PE fiber has high specific strength and can be used in bulletproof vests, bulletproof panels, etc. Due to the poor antistatic and clustering properties of PE, it can be used for the weaving of non-weft fabrics but is not conducive to the weaving of woven fabrics. Therefore, PE fibers are used in soft bulletproof vests and hard bulletproof inserts of individual protective equipment. Its main application The fabric forms are all non-woven fabrics. After years of development, the body armor made of soft PE non-woven fabric has reached a gram mass of ≤5.4kg/m², which can meet the requirements of level 2 protection in GA141-2010 “Police Body Armor”, and the V50 value can be Up to 630m/s. The combination of hard PE non-woven fabric and bulletproof ceramics can resist the attacks of various rifles, sniper rifles, armor-piercing incendiary bombs and other high-power bullets. In 2021, a new type of military bulletproof vest equipped with anti-53 armor-piercing incendiary bullet-reinforced bulletproof inserts will appear, as shown in Figure 6.

2.3 Shear thickening fluid body armor Shear thickening fluid (STF) is a non-Newtonian fluid. When the shear strain rate reaches a certain threshold, the viscosity of the fluid will instantly increase to hundreds or even thousands of times, realizing the transition from liquid to quasi-solid. change. Shear thickening liquid body armor is to infiltrate STF into high-performance fibers. In the non-protective state, the bulletproof material is in a soft state. When impacted by a bullet, STF hardens instantly, making the high-performance fiber stronger and forming a more effective blocking effect on the impact body. Compared with ordinary bulletproof materials, STF bulletproof materials are lighter and softer. At present, for higher impact speeds, the protective effect of STF bulletproof materials on body armor is not obvious, and further research is needed.

3 Wearing comfort of body armor The demand for body armor is not limited to high protective performance, but also requires features such as light weight, comfortable wearing, and good ergonomics. The bulletproof material adopts a reasonable structural design, which can improve the wearing comfort of the bulletproof vest. The wearing comfort of bulletproof vests is closely related to the clothing itself and the degree of fit. Therefore, bulletproof materials should choose fabrics with good flexibility and good air permeability. Yang Dan invented a three-dimensional front chest structure suitable for women’s body armor. The organizational structure is a combination of various structures. The warp and weft yarn materials are all aramid, which has good plasticity, conforms to body curves, is comfortable to wear, and has a good bulletproof effect.

Li Jinlu and others have developed a new type of inflatable protective heat sink for body armor, which can improve the uniform distribution of ergonomic load of the body armor carrier, reduce fatigue, increase endurance, improve wearing comfort, and can continuously dissipate heat for body armor. At the same time, the heat sink can Increase the contact distance between the human body and the bulletproof vest, reduce the damage to the human body when the bulletproof vest is hit by bullets, and improve the wearing safety. 4 conclusion Although body armor has good protective properties, it has a large mass and poor wearing comfort, which greatly affects the wearer’s flexibility and mobility. In the future, bulletproof vests should tend to be lightweight, modular, diversified, humanized, and comfortable. The upgrade of bulletproof materials and technical processes is one of the main ways to achieve the above goals. Improvements on the basis of existing bulletproof materials, so that they have functional characteristics that did not exist or make up for their shortcomings, or optimize and improve existing processes to obtain the best performance parameters of different bulletproof materials, can improve the performance of bulletproof vests Ballistic performance and comfort.