Introduction to Aramid Fibers

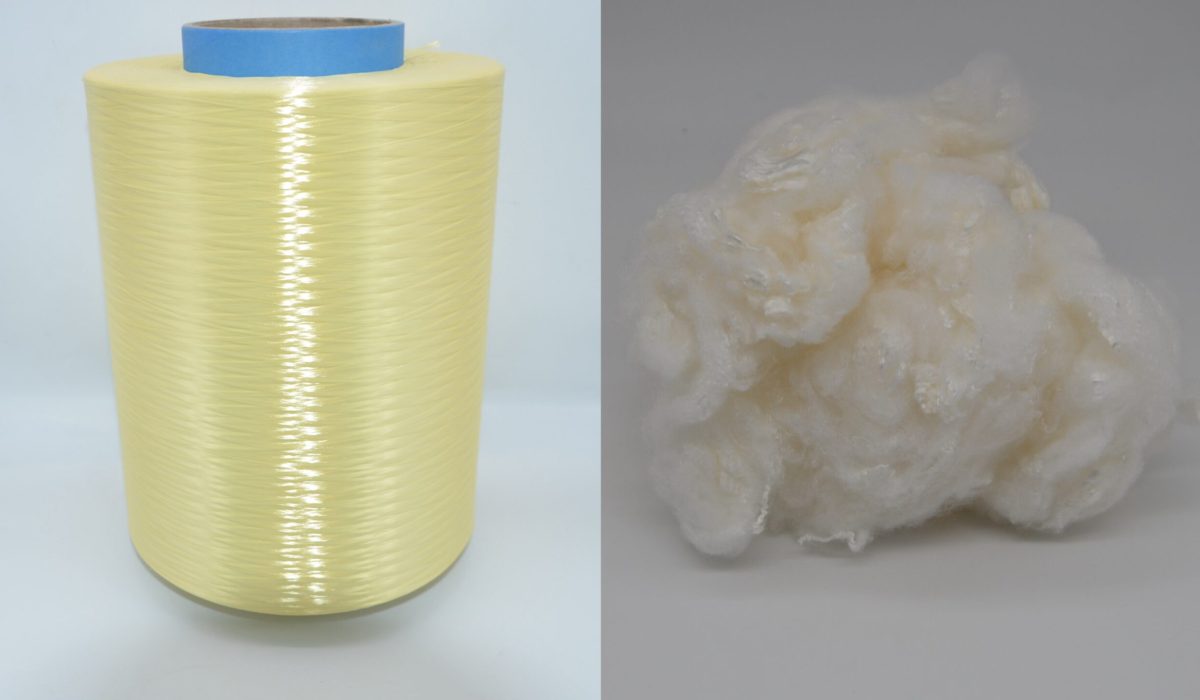

Aramid fibers, a class of high-performance synthetic fibers, are renowned for their exceptional strength, heat resistance, and durability. The two primary types are meta-aramid (Nomex®-type) and para-aramid (Kevlar®-type), each with distinct molecular structures that influence their properties and applications.

Para-Aramid Fibers (e.g., Kevlar®, Twaron®, VICWA®)

Advantages:

✔ Ultra-High Tensile Strength – Para-aramid fibers exhibit superior strength-to-weight ratios, outperforming steel in specific tensile strength.

✔ Outstanding Impact & Cut Resistance – Ideal for ballistic armor, bulletproof vests, and cut-resistant gloves.

✔ High Modulus & Dimensional Stability – Maintains structural integrity under stress, making it suitable for aerospace and composite reinforcement.

✔ Good Heat Resistance – Withstands temperatures up to 400°C (752°F) short-term without melting.

Disadvantages:

✖ Lower Thermal Stability Than Meta-Aramid – Degrades faster under prolonged high heat (>500°C).

✖ Sensitive to UV & Moisture – Requires coatings for outdoor applications to prevent degradation.

✖ Poor Compression Strength – Prone to microfibrillation under compressive loads.

Meta-Aramid Fibers (e.g., Nomex®, Teijinconex®, MICEX®)

Advantages:

✔ Exceptional Heat & Flame Resistance – Self-extinguishing and withstands continuous exposure to 200-250°C (392-482°F).

✔ Excellent Thermal Insulation – Used in firefighter gear, industrial protective clothing, and electrical insulation.

✔ Chemical & Radiation Resistance – Performs well in harsh environments, including acidic/alkaline conditions.

✔ Better Flexibility & Comfort – Softer than para-aramid, making it suitable for wearable applications.

Disadvantages:

✖ Lower Tensile Strength – Not ideal for load-bearing applications compared to para-aramid.

✖ Limited Ballistic Performance – Less effective in armor applications due to lower impact resistance.

✖ Higher Cost Than Conventional Fibers – More expensive than fiberglass or polyester.

Key Applications Comparison

| Property | Para-Aramid (Kevlar®-type) | Meta-Aramid (Nomex®-type) |

|---|---|---|

| Primary Use | Ballistic armor, composites, ropes | Fireproof clothing, electrical insulation |

| Max Temp. | ~400°C (short-term) | ~250°C (continuous) |

| Strength | Extremely high tensile | Moderate tensile |

| Flexibility | Stiffer | More flexible & comfortable |

Conclusion: Which Aramid Fiber to Choose?

- For extreme strength & ballistic protection → Para-aramid (Kevlar®-type)

- For flame resistance & thermal insulation → Meta-aramid (Nomex®-type)

Both fibers play critical roles in aerospace, military, industrial, and automotive sectors. Understanding their differences ensures optimal material selection for high-performance applications.