Research Background

Fabric-reinforced polymer composites play a vital role in lightweight structural components and functional devices across aerospace, transportation, and energy sectors. Similar to other composite materials, their macroscopic properties are governed not only by the fibers or polymer matrix but also by the fiber-matrix interface. Superior interfacial bonding ensures effective stress transfer, resistance to external impact, and long-term environmental durability. However, under tensile, impact, and sliding loads, poor interfacial adhesion often leads to premature fiber debonding—a primary failure mode that limits the full utilization of fabric-reinforced polymer materials.

Achievement Summary

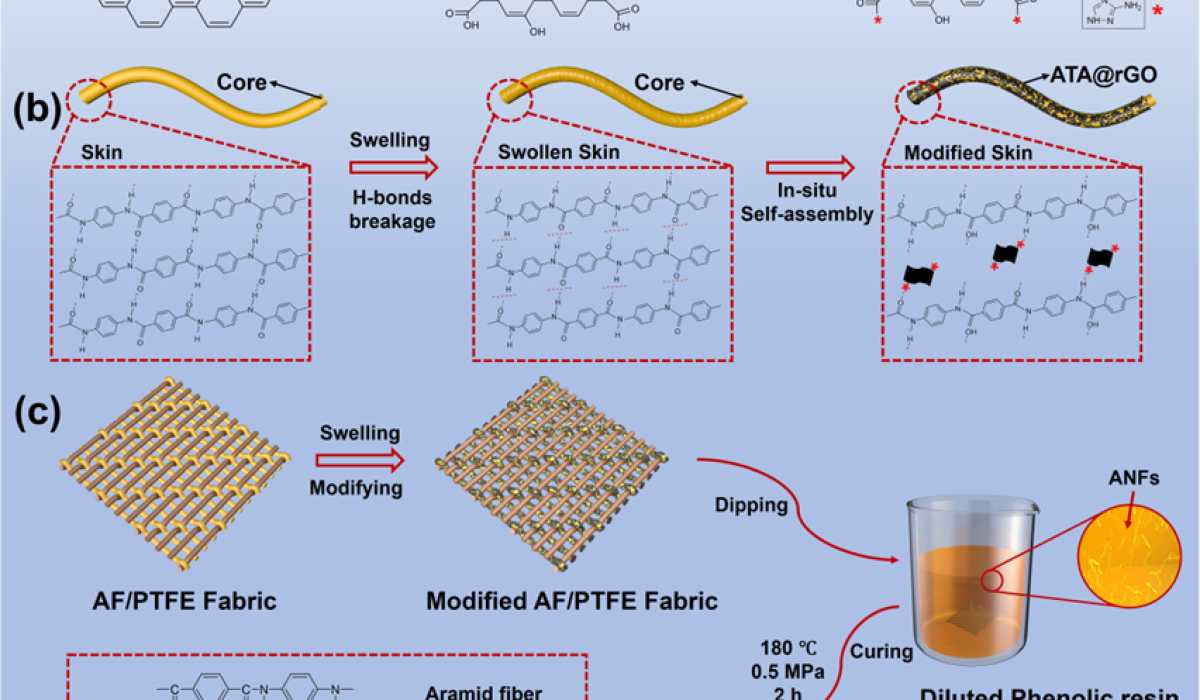

A recent study published in Advanced Functional Materials, titled “Micro-Swelling-Induced Nanostructured Hydrogen-Bond Network (MiNaHN) Integrates Inert Aramid Fibers into High-Strength, Wear-Resistant Fabric Composites,” introduces an innovative strategy for constructing a multi-hydrogen-bond network via micro-swelling. Jointly conducted by Prof. Xuqing Liu and Associate Prof. Ruisheng Guo from the Advanced Lubrication and Sealing Materials Research Center at Northwestern Polytechnical University, in collaboration with Prof. Zhaozhu Zhang from the Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences, the research presents a 3D continuous and strongly bonded nano-interface. This structure is synergistically formed by reduced graphene oxide nanosheets and aramid nanofibers through dynamic hydrogen bonding, effectively bridging the fiber framework and surrounding resin.

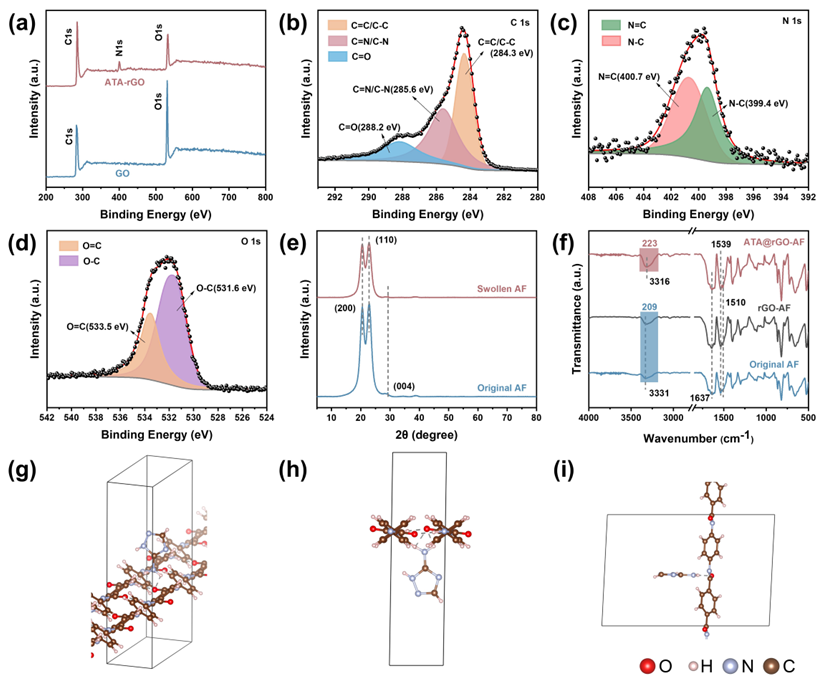

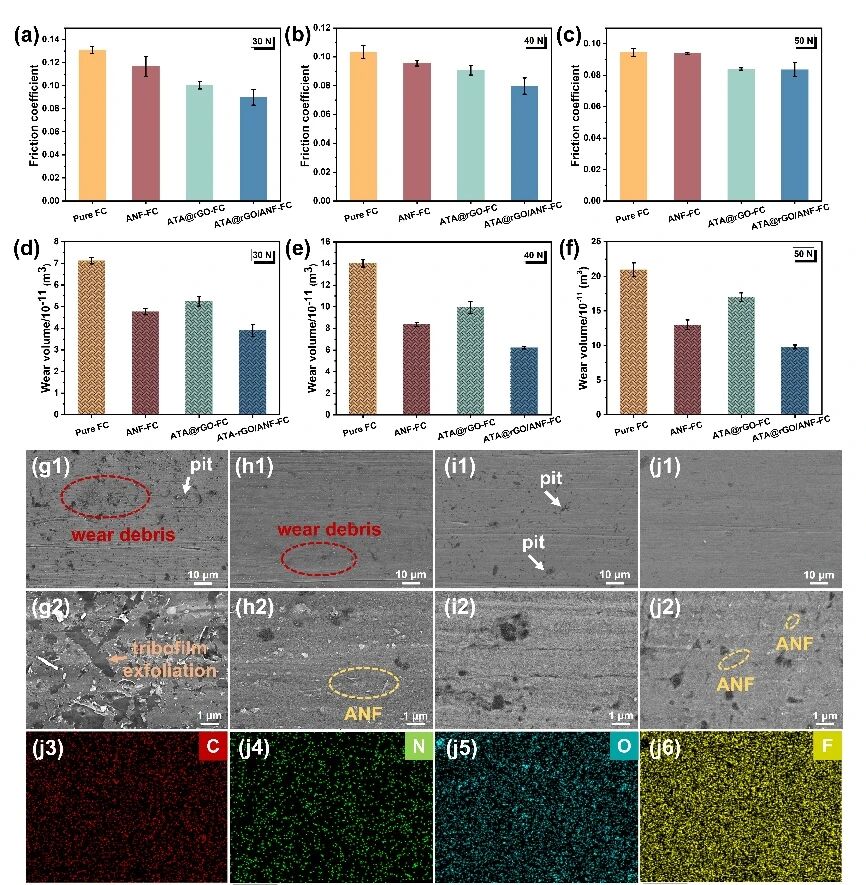

The integrated architecture delivers remarkable multi-faceted performance enhancements without compromising the inherent strength of the fibers. Specifically, the aramid/PTFE fabric composites exhibit a 71.9% increase in tensile strength, along with 45.4% and 31.5% reductions in wear volume and friction coefficient, respectively. This approach of activating the chemical inertness of organic fibers via nano-interfacial engineering demonstrates promising scalability, making it widely applicable to composite systems requiring simultaneous improvements in mechanical robustness and frictional stability.

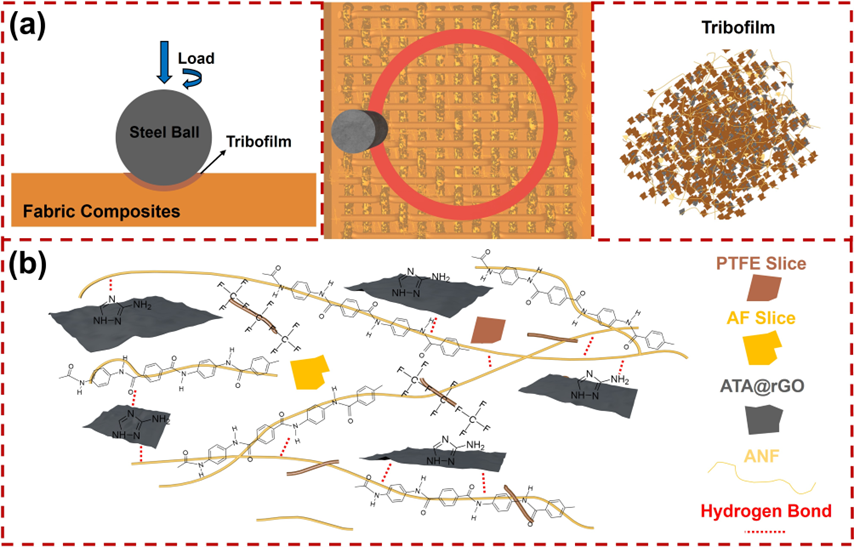

Figure 1. Illustration of the in-situ formation mechanism for a dynamic hydrogen-bonded network

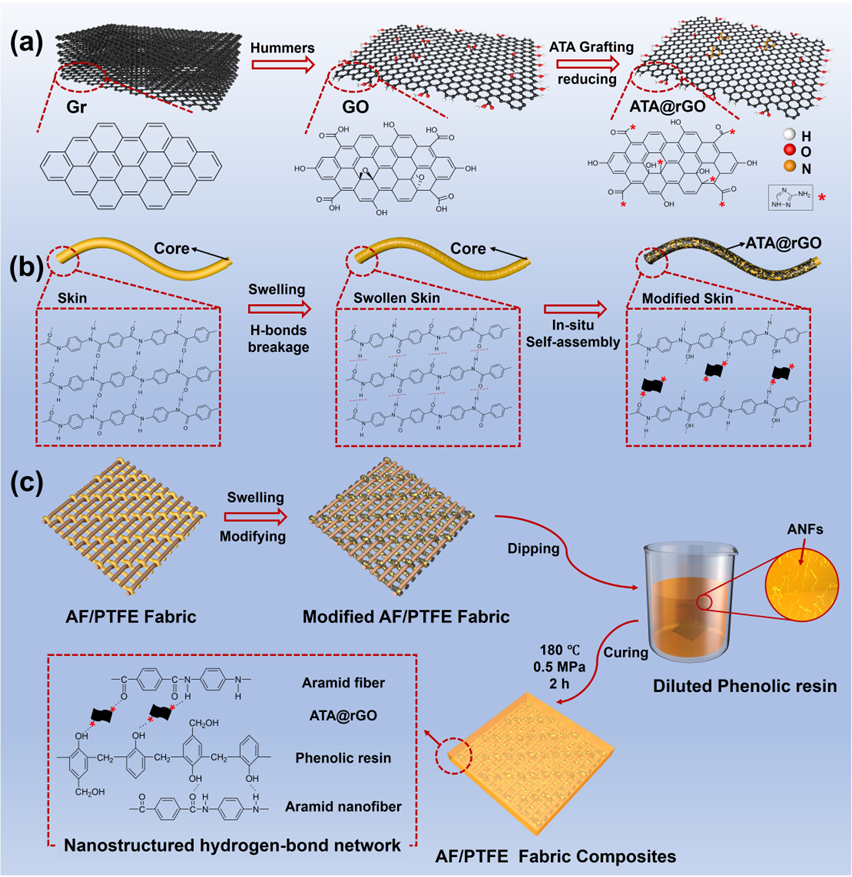

Figure 2. Chemical Composition and Dynamic Hydrogen Bonding Characterization

Figure 3. Enhanced Thermomechanical Properties via Hydrogen-Bond Network in Fabric Composites

Figure 4. Improved tribological properties of fabric composites by a hydrogen-bonding network

Figure 5. Illustration of Frictional Transfer Film Formation and Structure