Because of its high modulus, high strength, wear resistance, good insulation, and light weight, aramid fiber is widely used in rail transit, military, aviation and other fields, such as helicopter composite structural parts, strategic missile engine shells, Floors, ceilings, luggage racks, etc. of rail vehicles such as maglev trains and high-speed rail. However, the aramid fiber waste generated during the production process and the aramid fiber that loses its effectiveness due to aging of parts are often mistreated by landfilling, crushing, etc., resulting in a waste of precious resources and serious environmental pollution.

Aramid nanofibers (ANFs), as a new type of polymer nanofiber developed in recent years, not only retains the structural characteristics, excellent mechanical properties and thermal stability of aramid fibers; at the same time, its unique nanoscale morphology endows it with new the connotation and excellent characteristics of nanocomposites have attracted great attention in the field of nanocomposites, but the extremely high production cost hinders its large-scale application.

From the perspective of resource conservation and cost reduction, the research team of Shaanxi University of Science and Technology explored a highly feasible and cost-effective recycling method by using existing waste aramid fibers to make high-value-added aramid nanofibers.

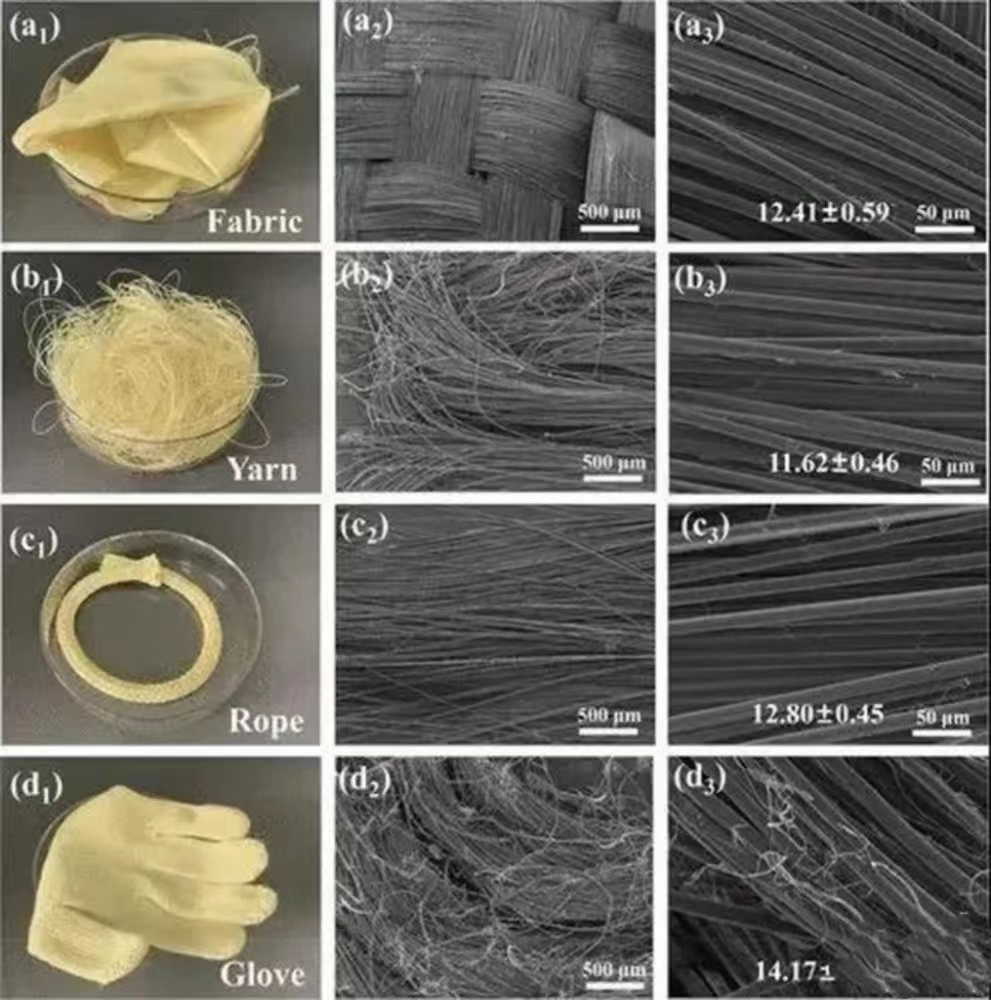

Aramid itself has high chemical resistance and does not melt. Except for being dissolved in concentrated acid solution, its solubility is extremely poor. Traditional chemical recovery and combustion waste heat recovery technologies cannot recycle aramid waste resources. The researchers report a proton donor-assisted deprotonation method to recover non-renewable aramid resources for the preparation of relatively low-cost high-performance ANFs.

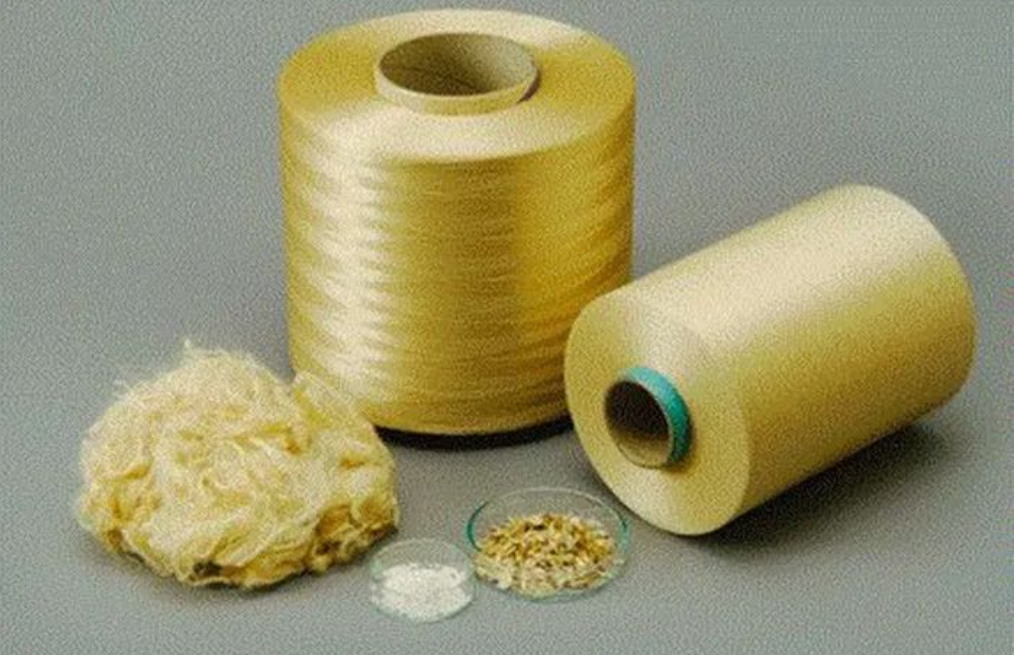

First, rinsing the aramid waste resource with acetone and deionized water removes absorbed impurities and gloss, giving it a bright yellow color. Then, ANFs were prepared from various aramid waste resources with a length of 2–20 cm and a diameter of 11–14 μm.

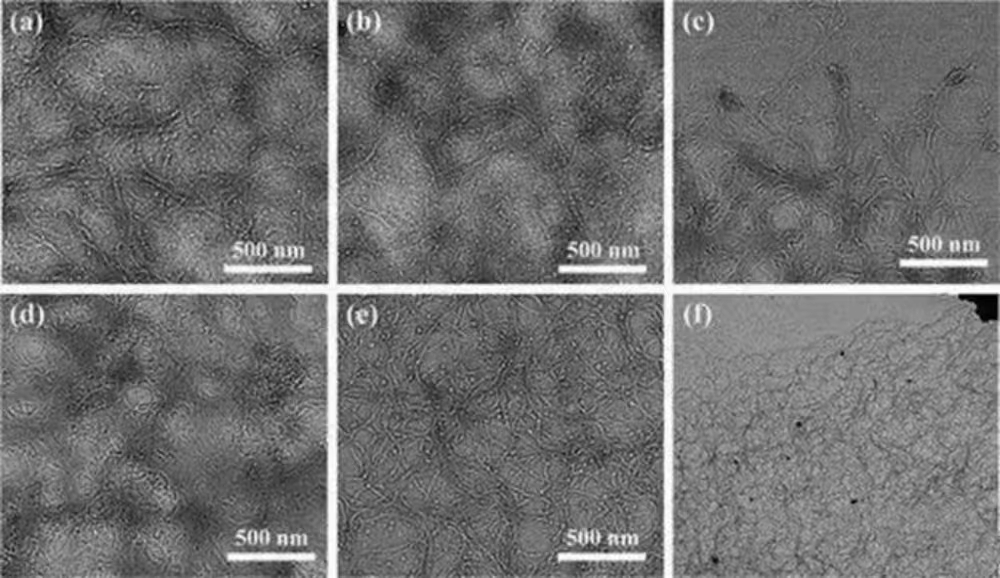

Fabrics or fibers were deprotonated in different concentrations of KOH/DMSO/H2O for 5 h. In this process, the aramid fiber gradually dissociates under the action of shear force and electrostatic repulsion, disintegrates along the axial/radial direction, and obtains smaller-scale ANFs with a diameter of 10-15 nm and a length of several microns, that is, a Deep red transparent ANFs/DMSO dispersion. The darker the solution, the higher the concentration of ANFs. Traditional deprotonation usually takes 7 days, and this research method greatly reduces the processing time.

From the nanostructure of ANFs, it can be seen that different recycled fiber morphology does have an impact on the nanomorphology of the prepared ANFs. Moreover, the characterization of various mechanical properties shows that the slender and hard nanostructure of ANFs and the dense network structure formed by a large number of hydrogen bonds between nanofibers are the reasons for its excellent tensile strength.

The strategy of recycling waste aromatic resources to prepare high value-added ANFs replaces the need to use expensive raw material resources, thereby reducing the cost of ANFs preparation. Compared with traditional recycling methods, recycled ANFs have significant advantages in size uniformity, dispersion, and film-forming properties.

The relevant research results were published on “ACS Nano” under the title of “Recycling of High-Value-Added Aramid Nanofibers from Waste Aramid Resources via a Feasible and Cost-Effective Approach”.