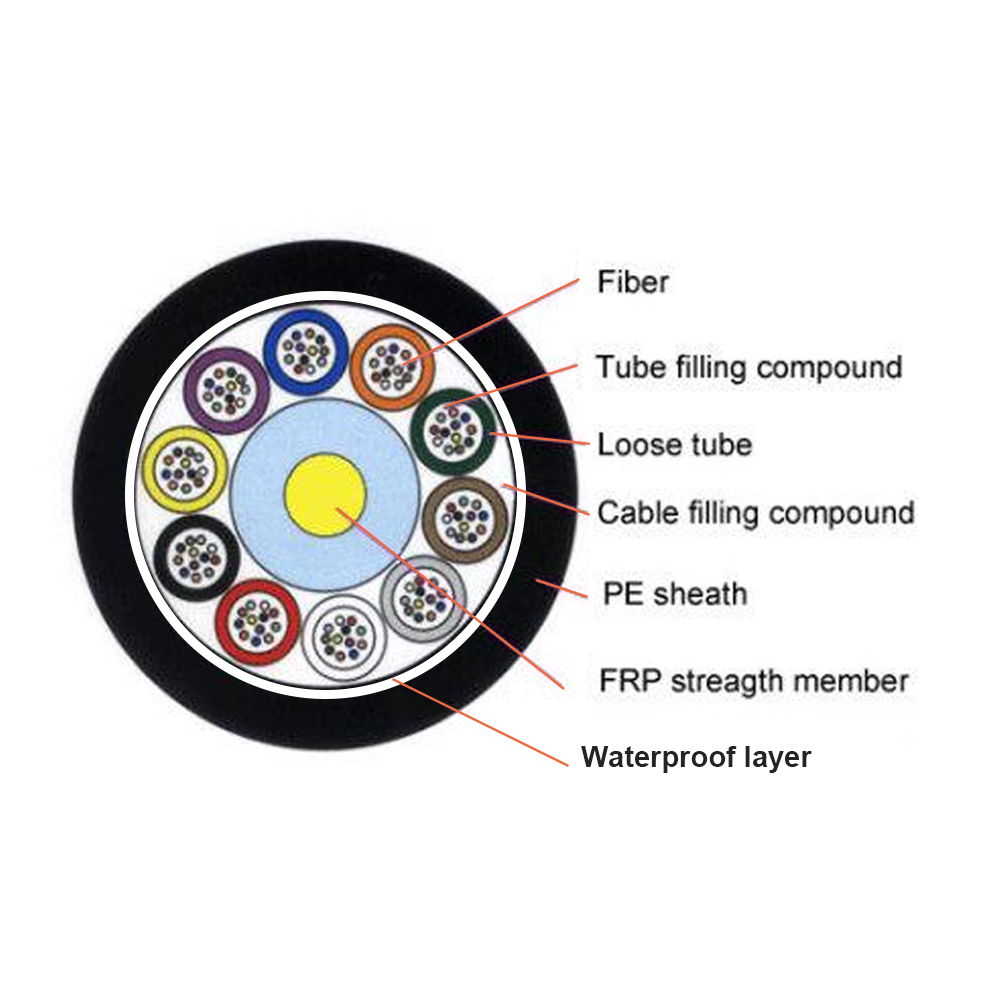

Strictly speaking, GYFTZY non-metallic flame-retardant optical cable (generally the power optical cable adopts the layer-twisted type) is not a special optical cable for our power optical cable. But when our power optical cable line enters the substation, the substation has a strong current occasion, and at the same time has high requirements for lightning protection and flame retardancy, so it is necessary to use non-metallic materials and optical cables with good flame retardancy. All of us in the substation section Generally, GYFTZY non-metallic flame-retardant optical cable is used. Some people may say, I think ADSS full-dielectric self-supporting optical cable can be used. According to the conditions of use of ADSS full-dielectric self-supporting optical cable, it is also suitable for lightning areas and strong electricity areas but compared to ordinary optical cables of GYFTZY non-metallic flame-retardant optical cables, The cost is high, and the price/performance ratio is not high.

We understand the performance of the optical cable through the letters of GYFTZY. GY is an outdoor optical cable for communication; F is a non-metallic strength member; T is a filled water-blocking; Z is flame retardant; Y is a polyethylene sheath. Through the above, we know that its technical characteristics are flame-retardant sheath, and the loose tube is filled with special ointment to provide key protection for the optical fiber. The full-section water-blocking structure ensures good water-blocking and moisture-proof performance of the cable. High-modulus glass fiber reinforced plastic rod (FRP) central strengthening member, the optical cable is an all-dielectric (non-metallic) structure, light in weight, easy to lay, and excellent in anti-electromagnetic ability, suitable for power systems and thunderstorm areas. The optical cable is generally laid through pipes in the station. The minimum bending radius is 20 times the outer diameter of the optical cable when laying; 10 times the outer diameter of the optical cable when the laying is completed.

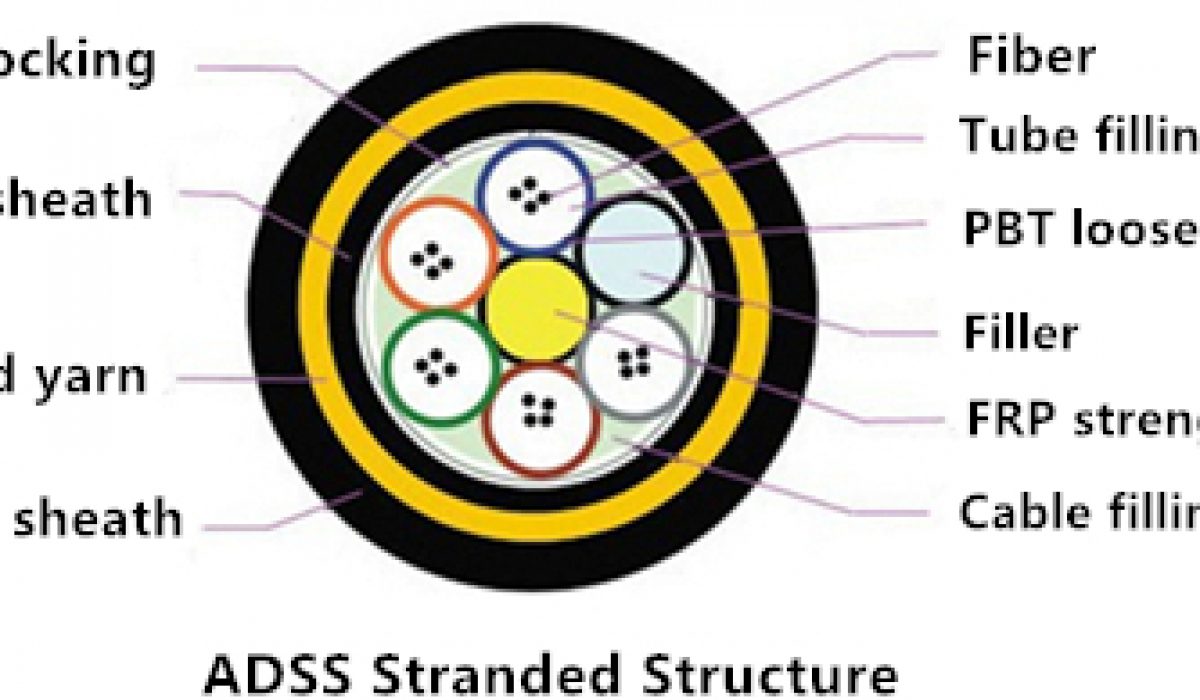

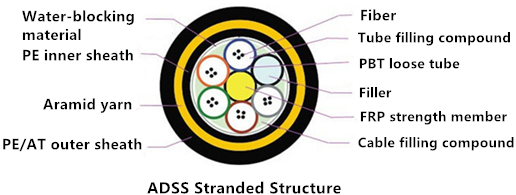

The ADSS optical cable adopts a loose-tube layer-stranded structure. The 250μm optical fiber is inserted into a loose tube made of high modulus material, and the loose tube is filled with a waterproof compound. Loose tubes (and filler ropes) are stranded around a non-metallic central reinforcement (FRP) to form a compact cable core, and the gaps in the core are filled with water-blocking grease. The inner sheath of polyethylene (PE) is extruded outside the cable core, and then the aramid fiber for reinforcement is stranded, and finally the outer sheath of polyethylene (PE) or electric tracking resistance (AT) is extruded.

Application: self-supporting overhead.

Features:

- It can be erected without interruption

- Using AT sheath, the resistance to electric tracking is superior

- Light weight, small cable diameter, reducing the impact of ice, wind and load on towers and supports

- Large span, the maximum span is more than 1000 meters

- Excellent tensile properties and temperature characteristics

- Life expectancy greater than 30 years

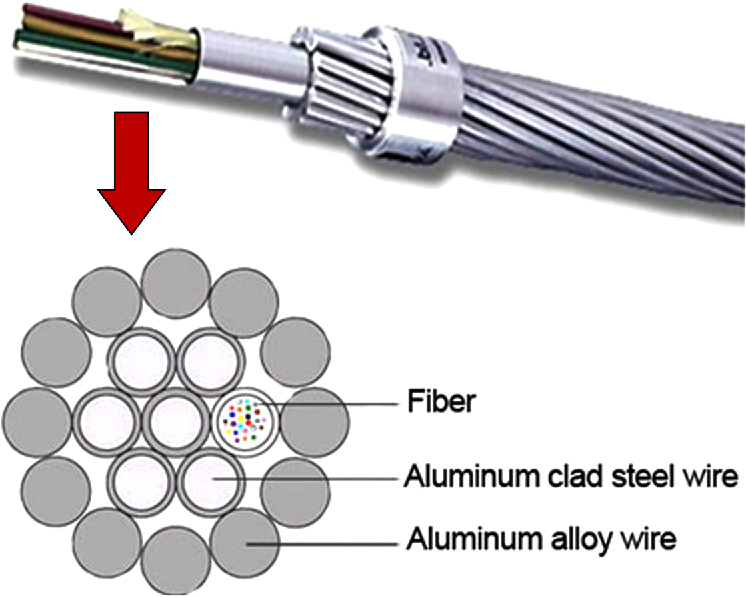

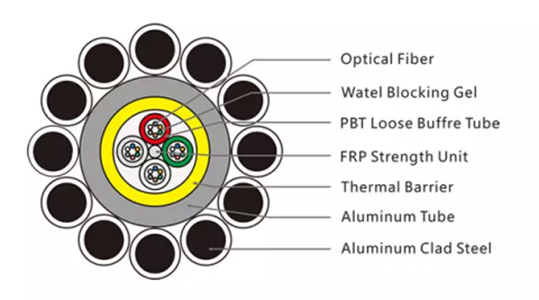

OPGW products integrate the functions of ground wire and optical communication, and are mainly used for communication lines of new overhead high-voltage transmission systems of 35KV and above, and can also be used to replace existing ground wires of old overhead high-voltage transmission systems, increase optical communication lines, and conduct short-circuit currents And provide anti-lightning protection.

Structural features of OPGW products: stainless steel tube optical fiber unit and aluminum-clad copper wire, aluminum alloy wire twisted and cabled; stainless steel tube optical fiber unit is located in the center or inner layer of the twisted layer.

Metal-free bundled aerial optical cable AD-Lash (All Dielectric Lashed Cable) and metal-free winding optical cable

GWWOP (GroundWireWrappedOpticalFiberCable) optical cables are sometimes collectively referred to as additional optical cables – OPAC, which is an economical and fast way to build optical fiber communication networks on power lines.

They use automatic binding machines and winding machines to bind and wind optical cables on ground wires or phase wires. Their common advantages are optical cables are light in weight, low in cost, and quick to install. It can be installed on the ground wire or 10kV/35kV phase wire without power failure; the common disadvantage is that since they all use organic synthetic materials as the outer sheath, they cannot withstand the high temperature generated by the phase wire or the ground wire when the line is short-circuited. The aging of the outer sheath material requires special machinery during construction, and there are many problems in terms of construction workability and safety, and it is vulnerable to external damage, such as bird damage, gunshots, etc., so it has not been solved in the power system. Wide range of applications. But in the world, this kind of technology has not been eliminated or abandoned, and it is still applied in a considerable range.

The optical fiber composite cable is mainly similar to OPPC. The optical fiber unit is combined with the cable, so that the cable has the dual functions of phase line and communication. Optical fiber composite cables include optical fiber composite low-voltage cables OPLC, optical fiber composite medium-voltage cables OPMC, and optical fiber composite high-voltage cables that are now used on high-voltage cables (such as 110kV submarine power cables, 220kV submarine power cables and some land cables).

Optical fiber composite medium voltage cable OPMC is a medium voltage intelligent composite cable for rated voltage 6kV ~ 35kV power supply system. Optical fiber composite medium voltage cable OPMC is a kind of optical fiber composite medium voltage cable, including cable core, cable core tape layer and outer sheath. There are power transmission wires and water-blocking fillers in the cable core. Each power transmission wire is composed of a conductor It is composed of a conductor shielding layer, an insulating layer, an insulating shielding layer and a metal shielding layer in turn, and a loose tube with an optical fiber inside is provided in the cable core, and a non-metallic strengthening layer and a sheath are sequentially covered outside the loose tube. An optical fiber communication unit composed of layers, an inner sheath and a steel tape armor layer are sequentially provided between the cable core tape layer and the outer sheath.