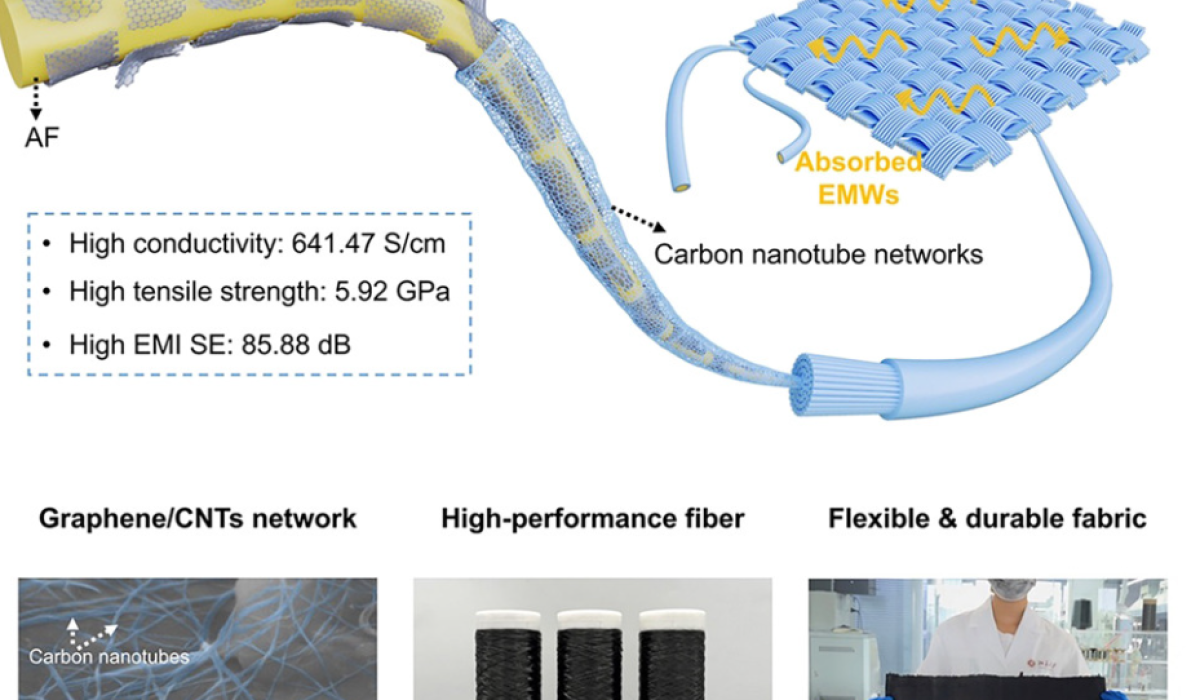

Meta Description: Researchers from Peking University develop a breakthrough dimension-engineered sequential assembly strategy for coating fibers with graphene & CNTs, enabling lightweight, flexible textiles with 85.88 dB EMI shielding.

Content:

A research team led by Assistant Professor Gao Xin at Peking University has unveiled a groundbreaking “dimension-engineered sequential assembly” strategy, successfully creating uniform and robust coatings of graphene and carbon nanotubes (CNTs) on various fiber substrates. Published in the prestigious journal Matter, this work tackles a central challenge in functional material science: how to integrate nanomaterials onto flexible fibers in a scalable and stable manner for high-performance electromagnetic interference (EMI) shielding.

The resulting fiber fabrics exhibit exceptional electrical conductivity, outstanding EMI shielding effectiveness (85.88 dB), remarkable mechanical strength, and excellent environmental stability. This provides an ideal solution for lightweight, flexible EMI shielding materials critical for aerospace, defense, and wearable electronics.

Addressing Key Technical Challenges

Previous attempts faced significant limitations:

- Lack of Uniformity: Individual 2D graphene or 1D CNTs struggled to form continuous, defect-free coatings on fibers, often leading to agglomeration and poor coverage.

- Weak Adhesion: Nanomaterial coatings frequently detached from the fiber substrate under bending, friction, or harsh conditions, causing performance degradation.

- Poor Scalability: Many lab-scale techniques were not suitable for large-scale industrial production.

The Innovative Solution: Dimension-Engineered Sequential Assembly

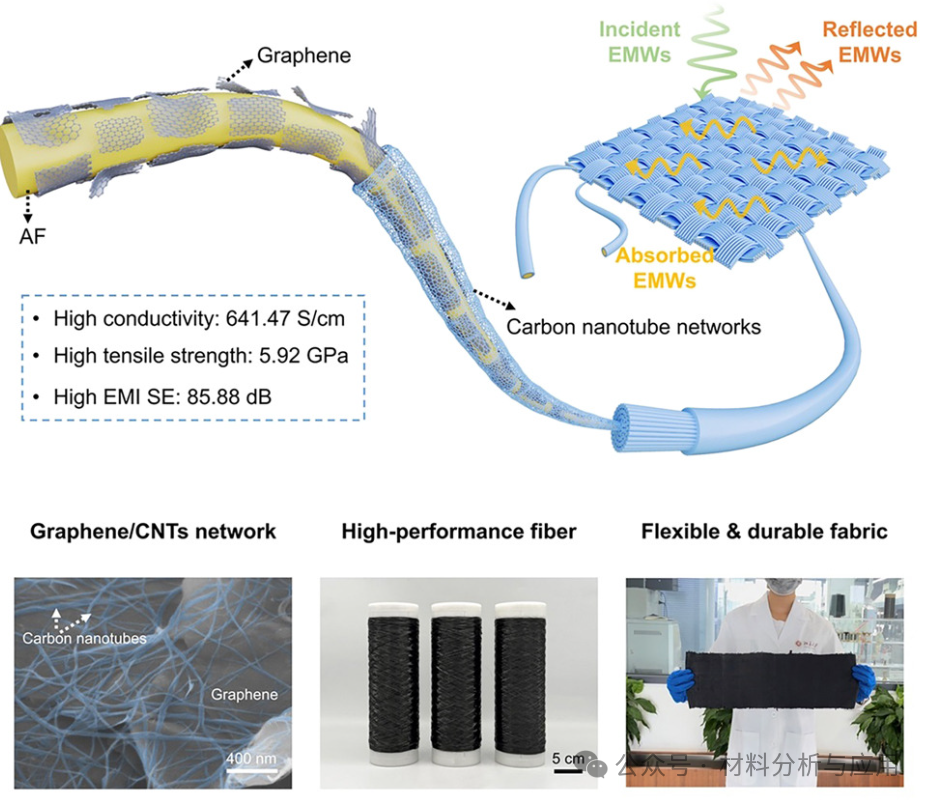

This novel strategy cleverly leverages the geometric complementarity of nanoscale materials with different dimensions, building a stable coating like constructing a wall:

- Step 1: Laying the “Foundation”

- 2D Graphene Nanosheets are first deposited. Their planar structure allows them to adsorb and form an initial, continuous conductive base layer on the fiber surface, ensuring primary coverage.

- Step 2: Filling and “Binding”

- 1D Carbon Nanotubes are subsequently introduced. Acting like countless microscopic ropes, the CNTs:

- Bridge: Connect adjacent graphene sheets, filling the gaps to create a denser conductive network.

- Wrap: Entangle around the graphene-coated fiber, compressing and reinforcing the entire coating for mechanical robustness.

- Form a 3D Network: Collaborate with graphene to build a stable, continuous 3D sp²-carbon conductive architecture.

- 1D Carbon Nanotubes are subsequently introduced. Acting like countless microscopic ropes, the CNTs:

Core Concept of Dimension Engineering: By precisely controlling the deposition sequence of 1D and 2D nanomaterials and utilizing their respective geometric advantages, a synergistic “1+1>2” effect is achieved, resulting in a perfectly conformal and sturdy coating on complex fiber surfaces.

Performance Metrics & Results

Using aramid fiber (AF) as a model substrate, the team produced Graphene/CNT-coated Aramid Fibers (GCAFs), which were woven into a fabric (GCAFF) demonstrating impressive properties:

- Exceptional Mechanical Strength:

- The composite fiber retains a high tensile strength of 5.92 GPa, inheriting the robustness of the aramid core.

- High Electrical Conductivity:

- Achieves a conductivity of 641.47 S/cm, forming the foundation for effective EMI shielding.

- Top-tier EMI Shielding Effectiveness (SE):

- In the X-band frequency range (8.2-12.4 GHz, commonly used in radar), the fabric boasts an average SE of 85.88 dB.

- This signifies it can block over 99.999998% of incident electromagnetic wave energy, a performance level far exceeding the 20-60 dB requirement for many commercial applications.

- Robust Environmental Stability:

- The shielding performance remains stable under harsh conditions, including high temperature, humidity, chemical exposure, and mechanical abrasion, proving the durability of the coating.

Significance and Future Prospects

The impact of this research extends far beyond its impressive performance data:

- Solves a Core Manufacturing Problem: It offers a scalable and universal solution. “Scalable” indicates potential for industrial mass-production, while “universal” means it can be applied to various fiber types (e.g., glass, carbon, polyester), vastly broadening its applicability.

- Enables Structural-Functional Integration: The resulting fibers are not only functional for shielding but also maintain the high strength and low weight required for structural materials, crucial for weight-sensitive applications like aerospace and wearables.

- Opens New Design Avenues: The “dimension engineering” paradigm provides a new theoretical guide and design framework for creating other functional nanocomposites, potentially applicable in sensing, energy storage (flexible batteries/supercapacitors), and thermal management.

- Advances Next-Generation Flexible Electronics: It paves the way for developing truly comfortable, durable, and high-performance smart textiles and flexible electronic devices.

Conclusion

Peking University’s pioneering research, through its ingenious dimension-engineered sequential assembly strategy, masterfully combines the strengths of graphene and carbon nanotubes. It successfully fabricates high-performance EMI shielding fibers that are efficient, environmentally stable, and amenable to large-scale production. This achievement represents a significant breakthrough in materials science and smooths the path for the future development of advanced flexible electronics and protective gear.