Whether or not you ride motorcycles or are someone whose day-to-day life involves the need for serious full-body protection, you’ve probably heard the word ‘Kevlar®’. It’s one of the most well-known kinds of armor in the world, popular for its impact resistance and lightweight design. It’s used to make cut-resistant gloves, bulletproof vests, and even in aerospace engineering to create durable aircrafts–– but it’s certainly not the only name in armored fiber touted for its incredible range of use and durability.

Perhaps a lesser known name in armored fabric is ‘aramid.’ Maybe you’ve heard of aramid cord belts or aramid fiber gloves, but what’s the actual difference between aramid and Kevlar®? You might be surprised to know that they’re almost the same thing, but there are a few minor differences that are important to know.

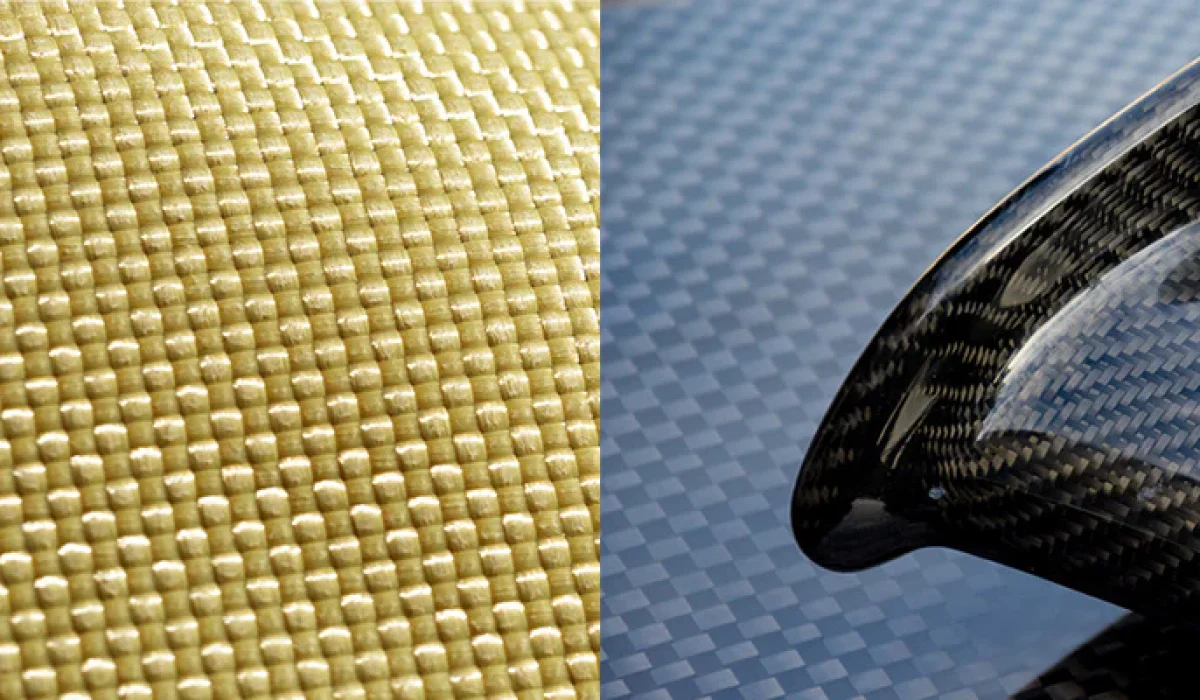

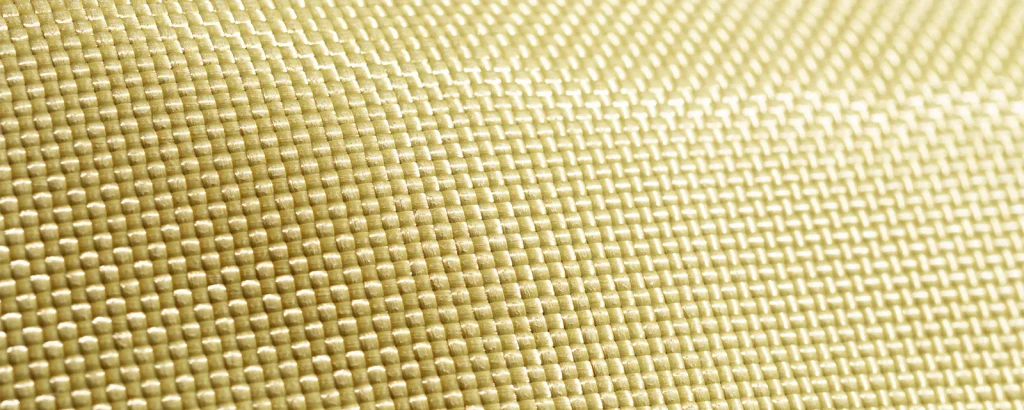

What are Kevlar® and Aramid Fibers?

Simply put, aramid is the general name for a strong and heat-resistant class of fibers. Branded names for aramid fibers include Twaron, Vicwa, and Kevlar®. Kevlar® is the trademarked name for aramid fiber made by DuPont, one of the world’s largest producers of science based products. Kevlar® is an incredibly strong and heat-resistant synthetic fiber that was invented by DuPont chemist Stephanie Kwolek in 1965. At the time, a gasoline shortage loomed on the horizon, and DuPont’s mission was to develop a light but strong fiber replacement for the steel wires used in car tires in order to improve gas mileage. Kwolek’s main job was to develop a version of a strong fiber that would be able to be spun and manipulated at a temperature lower than 400 degrees Fahrenheit.

After daily experimentation, Kwolek developed a fiber whose molecules would arrange themselves parallel to the length of the fiber in order to form strong hydrogen bonds within the molecule chains, resulting in a material five times stronger than steel and lighter than fiberglass that could also withstand up to 800 degrees Fahrenheit. Her development, branded as Kevlar®, solved the issue that DuPont had originally proposed, but she had unknowingly come up with something that would go on to save thousands of lives in the form of bulletproof vests, body armor, boots, gloves and so much more.

What is Carbon Fiber?

As I’m sure you know, carbon fiber is another material popular among motorcycle enthusiasts. You’ll find carbon fiber helmets, jackets, and gloves that claim to be among the strongest of the strong. Since aramid and Kevlar® are essentially one in the same, a better question to ask as a motorcyclist might be: what’s the difference between carbon fiber and Kevlar®/aramid fiber?

Carbon fiber is touted for its impressive strength despite it’s lightweight construction. It’s composed of microscopic strands or tows, allowing it to be woven for different purposes. The main difference between carbon fiber and Kevlar® is subtle to the eye but is an important one to note: carbon fiber is more brittle than aramid fiber, but it is stronger and more highly conductive. Kevlar®/aramid also has a lower tensile strength than carbon fiber, meaning its more likely to break under tension/pressure.

So, what does this mean for the kind of gear you should choose? Both work well for many applications, but wearable components that will potentially experience a high-force impact would be more effective if made from aramid fibers. We need this for abrasion resistance in the case of a motorcycle accident. The flexibility of aramid/Kevlar® without the brittleness makes it perfect for lining motorcycle gear like gloves, pants, jackets, and more. Components that remain rigid and would benefit from increased compressive strength would be best constructed from carbon fiber.

Which Material is the Best for Motorcycle Protection?

A Kevlar®-lined reinforced riding jacket or hoodie, like our Armored Black Reflective Performance Hoodie or Armored Riding Hoodie, is going to give you increased defense against abrasion and impact. Even with leather gear, an added layer of Kevlar® will give you that much more protection against serious injury due to its anti-ballistic properties. There’s a reason Kevlar® is used in car tires and on aircraft bodies! To be on the safest side yet, which is what we strive for when we ride our bikes, adding armor like our Phantom Tripleflex Level 2 Armor Set to your riding pants or jacket will get you the most protection possible (see here why you want Level 2 armor instead of Level 1).

The best context for carbon fiber is in motorcycle helmets and parts, where lightweight compressive strength is paramount.

Aramid versus Carbon fiber is almost like comparing a tote bag to a basket when it comes to the way the material behaves. But in short, Kevlar® for body protection, carbon fiber for parts on the bike or rigid components on accessories.

By Meghan Stark on November 10, 2022