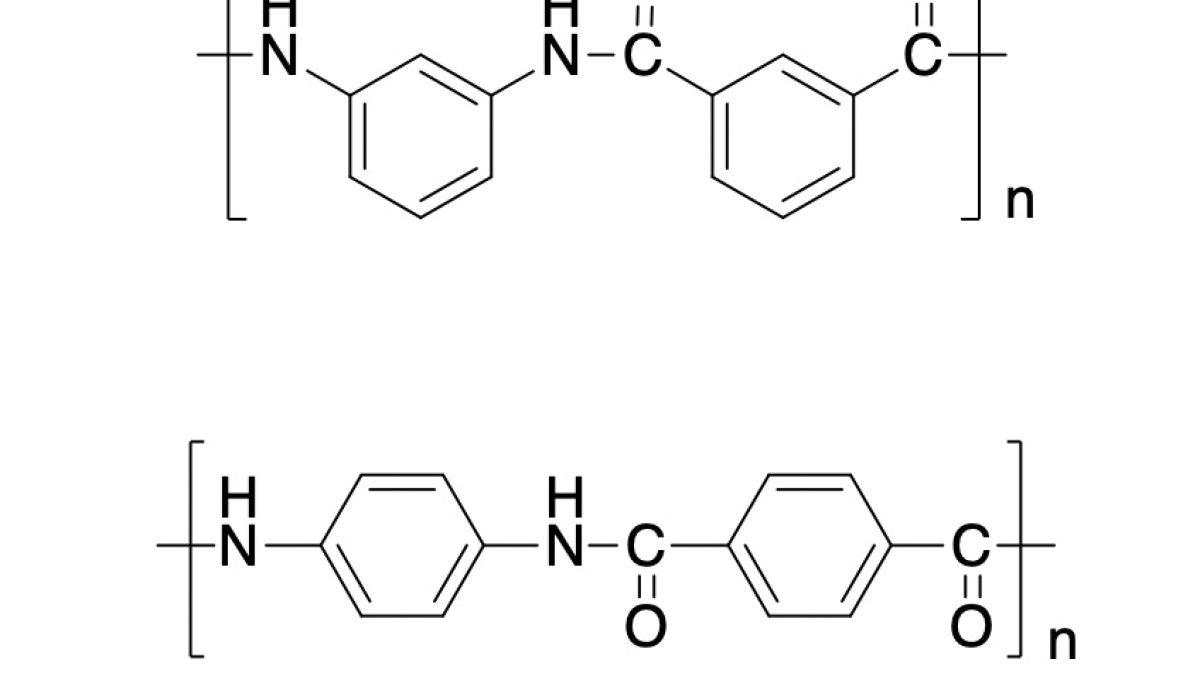

2. Modification of aramid fiber

Due to insufficient activation properties on the surface of aramid fiber, aramid fiber will be subject to many restrictions in the application process. Therefore, the modification of aramid fiber can increase the scope of use. The modification of aramid fiber either focuses on the smooth surface of aramid fiber, by reducing the molecular orientation along the axial direction of the fiber surface, improving the roughness of the fiber surface, increasing surface polarity, and improving the wettability of the fiber and the matrix; Either by increasing the active groups and “bridge” groups on the fiber surface, and by functionalizing the fiber surface, the obtained active groups or “bridge” groups can be combined with the matrix through chemical bonds or physical effects to improve the interaction between the matrix and the fiber. The interfacial bonding strength between them.

The modification methods of aramid fiber mainly include physical and chemical modification. Physical modification mainly includes plasma technology, ultrasonic impregnation technology, γ-ray modification, cryogenic treatment, heat treatment, supercritical CO2 treatment, surface coating technology and complex modification; chemical modification mainly includes surface etching and surface chemistry. Grafting, biological enzyme grafting.

2.1 Physical etching modification

The physical etching modification of aramid fiber mainly uses plasma, ultrasonic waves, etc. to act on the surface of aramid fiber to improve the surface roughness of aramid fiber.

Yu Ronglu and others used plasma to modify the surface of para-aramid fiber, and then used epoxy resin acetone solution to coat the fiber surface. The oxygen content on the surface of para-aramid fiber increased, and the surface layer of the fiber surface showed fibril peeling, peeling, and The bonding capabilities of the epoxy resin matrix are improved on several sides.

Liu Pengxiang developed a plasma technology that uses an extremely fine wire double-helical electrode structure to physically modify the aramid fabric and insert acrylic monomer. The surface of the fiber is rough, with obvious pits and protrusions. The specific surface area increases, the water contact angle decreases, and the surface free energy increases by 64%. The optimal treatment time is 120 seconds. It is used in aramid cord to enhance the adhesion between it and rubber.

2.2 Chemical etching modification of aramid fibers

The etching chemical modification of aramid fiber is mainly through reaction with specific chemical reagents, which hydrolyzes the amide bonds in the surface main chain, producing many microfibril structures, destroying the high crystallinity on the fiber surface, and increasing the surface roughness. , and at the same time, some chemical reagents can also introduce active groups such as amino groups. Commonly used treatment media mainly include inorganic acids or inorganic neutral solutions and organic solutions. Etching aramid fibers with inorganic solutions will generally significantly reduce the strength of aramid fibers. Therefore, for composite materials that require higher strength, inorganic reagents are generally not used, and even if they are used, the degree of treatment needs to be strictly controlled. Organic reagents can not only etch the surface of the aramid fiber, but also introduce some groups and functional groups without causing damage to the main body of the aramid fiber.

Xie Youju et al. used phthalic anhydride to chemically etching aramid fiber plain fabrics. The roughness of the fiber surface, the polar functional groups on the fiber surface, and the chemical bonding with the resin matrix were enhanced. Aramid fiber and its composite The properties of the material are improved.

2.3 Chemical graft modification

Luo Linzong and others used sodium dimethylsulfite solution to treat aramid fibers, and the surface amide bonds generated active sites, and then grafted them with trichloropropyltriethoxysilane (KH230) and allyl chloride respectively to prepare Modified aramid/carbon black/natural rubber composite materials are produced. After graft modification of the former, -C-si- stretching vibration absorption peak appears on the surface of aramid fiber, and the Si content increases; after graft modification of the latter, the C content increases and the O content decreases, and the natural rubber and Improved interfacial compatibility of aramid fibers. Moreover, after grafting and modifying the aramid fiber, the surface roughness, composite tensile strength, and elongation at break are increased, the crystal structure is not affected, and the crystallinity is reduced.

Liu Qian and others used phosphoric acid combined with ultrasound to etch para-aramid fiber. After modification, the surface roughness and specific surface area of para-aramid fiber increased, oxygen-containing polar groups were introduced, and the sedimentation volume increased by 57.14%. , reaching 220 mL, the dynamic contact angle is reduced, and the water wettability, water dispersibility and hydrophilicity of the fiber are enhanced. The fiber still maintains high crystallinity and good thermal stability, and the modification causes little damage to the aramid fiber.

Li Cuiyu and others used aluminum chloride and KH560 ethanol solution to modify aramid fiber. The surface roughness and surface energy of the fiber increased, the contact angle decreased by 38.16%, and the interfacial bonding force between the resin fibers was enhanced, which improved the tensile strength of the composite material. The elongation strength, extraction force, and strength of the fiber itself are reduced by 2%, effectively improving the performance of composite materials. Wang Zejia used two surface modification methods to modify aramid paper: treating it with 2% chlorosulfonic acid for 10 minutes at 50°C and soaking it in 100% acetic anhydride for 1 minute and then treating it with methanol for 3 minutes. Performance has little impact. Li Cuiyu and others used a silane coupling agent to modify aramid weft plain knitted fabrics, and then prepared composite materials through a vacuum-assisted resin transfer molding process. The maximum bending load, maximum impact load, and The maximum tensile load increased by more than 30%, and the maximum compressive load increased by nearly 25%.

Yang Chen and others used liquid ammonia to conduct ultra-low temperature treatment of para-aramid fiber, and no change in the molecular structure of the fiber occurred. There are holes appearing on the fiber surface, the roughness increases, the proportion of amorphous zone increases, the specific surface area increases, the fiber surface friction factor is optimally improved within 1 to 2 hours of processing, the dyeing adsorption performance is improved, and the crystallinity, molecular weight, and intrinsic viscosity are , the degree of polymerization decreases slightly, within the controllable reduction range of breaking strength (about 20%), the dynamic and static friction factors can be greatly increased, and the dyeing performance is improved.

Yue Pengfei and others used Lewis acid/CaCl2/ethanol solution to treat aramid fiber. Grooves were produced on the surface of the fiber, the roughness and specific surface area increased, the crystallinity decreased, and the chemical groups and elemental composition of the surface changed. The contact angle becomes smaller, the wettability of the fiber is increased, and the thermal stability does not change much.

2.4 Spinning modification

Cao Kaikai and others used meta-aromatic polyamide resin (containing imidazole structure) obtained by low-temperature solution condensation polymerization, and then spun it through dry and wet methods to obtain a modified aromatic polyamide resin with excellent thermal (oxygen) stability and flame retardancy. Polyester filament, with excellent mechanical properties and a limiting oxygen index of 46%. The ignition temperature of the glow yarn reaches 930 ℃ and the flammability index is 960 ℃. The thermal stability in the air is better than that of chlorine. The flame retardant grade is V-0.

3. Research on dyeing and printing of aramid fiber The color of aramid fiber is mainly dyed by carrier, non-water medium

The color of aramid fiber is mainly achieved through carrier dyeing, non-aqueous medium dyeing and structural coloring. Carrier dyeing is to dye aramid fibers by adding carriers to adjust the movement of fiber macromolecular chains, change (lower) the glass transition temperature of aramid fibers, and weaken intermolecular hydrogen bonds. The non-aqueous medium mainly uses solvents to change the fiber aggregation structure and swell the aramid fibers. At the same time, the aggregate morphology and structure of the disperse dyes are regulated, prompting the dye molecules to diffuse into the aramid fibers for dyeing. Structural color generation is the introduction of nanoparticles, adjusting the shape and size of nanoparticles, changing the color of fabrics, or adding high refractive index substances to build periodic nanostructures. It is an environmentally friendly color generation method that relies on nanoparticles or photonic crystals. Structure and arrangement.

3.1 Dyeing of meta-aramid fiber

Due to the high crystallinity and symmetrical molecular structure of meta-aramid, as well as the steric hindrance effect caused by a large number of benzene rings in the molecular structure, it is difficult for the amide bond to react chemically with other groups, resulting in low fiber surface activity and difficulty in dyeing. At present, meta-aramid mainly has several dyeing methods: dope dyeing, solvent dyeing, carrier dyeing and surface modification dyeing. Among them, dope dyeing is not suitable for flexible small-scale dyeing, and it is relatively difficult to control the color. Therefore, in large-scale single aramid dyeing, dope-dyed aramid fibers are widely used in research. Solvent dyeing mainly uses an anhydrous or less water system for dyeing. Due to the difficulty of solvent recovery and high equipment requirements, the current application has not been industrialized. Therefore, carrier dyeing and surface modified dyeing are the focus of research on meta-aramid.

The existence of amide bonds will also lead to poor light fastness of meta-aramid fabrics after dyeing. Therefore, improving the light fastness of meta-aramid fabrics is also the focus of current research. Zhang Shuai and others studied the disperse dye dyeing, cationic dye dyeing and paint ink dyeing of meta-aramid fabrics, and found that the molecular structure of meta-aramid contains a large number of amide bonds, which will cause damage when exposed to sunlight (especially ultraviolet light less than 400 nanometers). Breakage, oxidation, and yellowing. And as the sunshine time increases, the yellowing becomes more serious, which intensifies the sun discoloration of meta-aramid fiber. This is also an important reason for the poor color fastness of meta-aramid fiber Secondly, after long-term sunlight exposure of aramid fabrics dyed with disperse dyes, the surface of the meta-aramid fabric has been severely damaged. Disperse dyes generally can only enter the surface of the meta-aramid fiber. With the serious damage to the surface, the dye and damage The fibers fall off together, causing the fabric to fade. Aramid fabrics dyed with cationic dyes often fade because the dyes are destroyed by ultraviolet oxidation. When using 1% to 6% (owf) dyes for dyeing, it was found that the greater the amount of dye, the better the light fastness. In order to improve or use meta-aramid fabrics in areas where higher color fastness is required, paint dyeing can be used, and its sun fastness can reach level 4.

3.1.1 Carrier staining

Zhang Shuai et al. used 3% (omf) Dispersed Blue 73, 1g/L diffusing agent NNO, and a liquor ratio of 1:50 at 140°C. The pH value is 5~6, and the temperature is maintained for 45 minutes. Adding the self-made additive carrier EA-1 can effectively improve the K/S value of meta-aramid fabrics dyed with high-temperature and high-pressure disperse dyes. The higher the concentration of the carrier added, the darker the color obtained. At the same time, acid treatment of meta-aramid fabrics before dyeing can increase the dyeing color yield. Among them, meta-aramid fabrics dyed with Disperse Red W-4BS-01, Disperse Yellow 64, and Disperse Blue 73 have better light fastness.

Shang Runling and others used self-made amide carriers to dye meta-aramid fabrics with cationic dyes. When dyeing dark colors with 5.5% (owf) cationic dyes, a carrier of 50 g/L ~ 55g/L needs to be used, pH 4 ~ 4.5 , 40g/L~45g/L NaCl, kept at 130℃ for 50~60 minutes, can effectively improve the K/S value of meta-aramid fabric. Sunlight fastness is level 3-4, dry and wet rubbing color fastness, washing discoloration and staining fastness can all reach level 4-5.