Conclusion

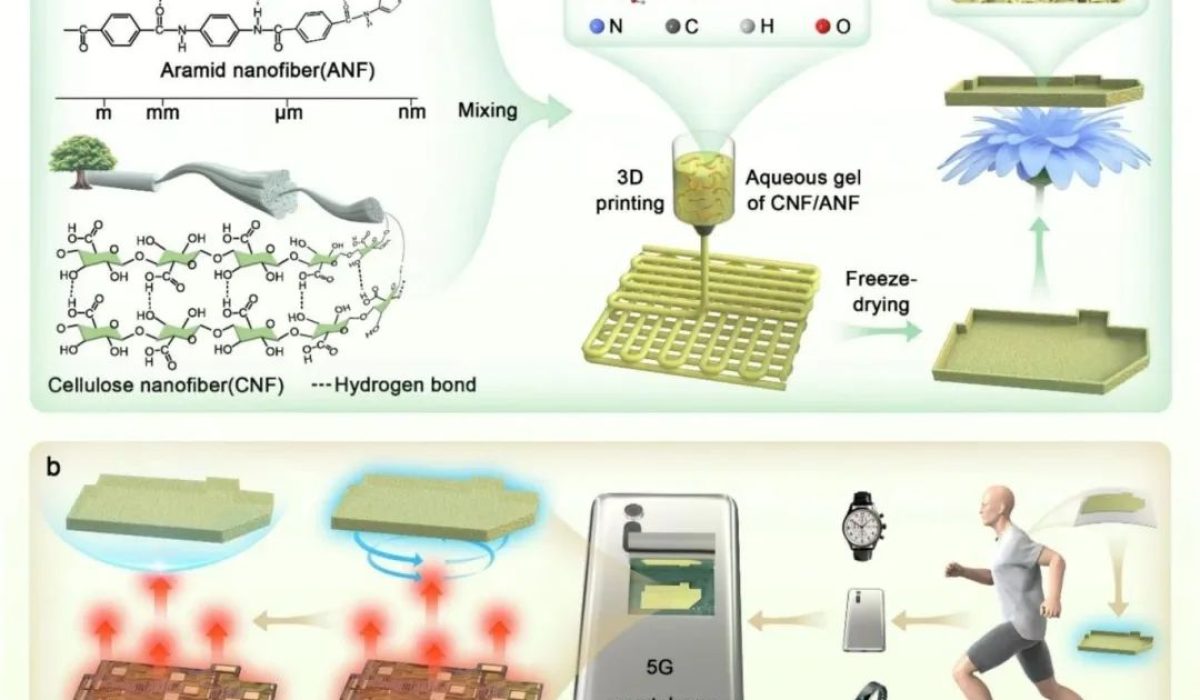

This study created customizable 3D-printed hybrid aerogels. It combined CNF and Aramid Nanofibers for a synergistic effect. This yielded enhanced mechanical properties and thermal stability. The C/A50% aerogel’s compressive modulus is ten times higher than pure CNF. This is due to Aramid Nanofiber rigidity and strong interfacial adhesion. The hybrid aerogel has a unique porous and entangled structure. This results in an ultra-low density of 12-16 mg/cm³. It also achieves very low thermal conductivity of 0.032-0.034 W/(m·K). The C/A hydrogel served as a 3D printing ink. It produced aerogels with custom architectures. These are ideal for insulating portable electronics. The thermal management capability was successfully tested. It was demonstrated on a 5G smartphone motherboard. The aerogel showcased outstanding insulation. It provides a scalable green solution. This solution is for thermal management in next-generation high-power devices.

Innovation Points

The research utilized hydrogen bonding between TEMPO-CNF and ANF. Bonds formed between the -COOH and -CONH- groups. This created a high-density network. It enhanced the macroscopic compression modulus. The aerogel maintained its lightweight properties.

Key Takeaway

This work combines flexible CNF with rigid Aramid Nanofibers. CNF offers low thermal conductivity and is biodegradable. Aramid Nanofibers provide high heat resistance and high modulus. These complementary binary nanofibers enable simultaneous optimization. They enhance mechanical strength, improve thermal resistance, and ensure printability. All are achieved within a single network.