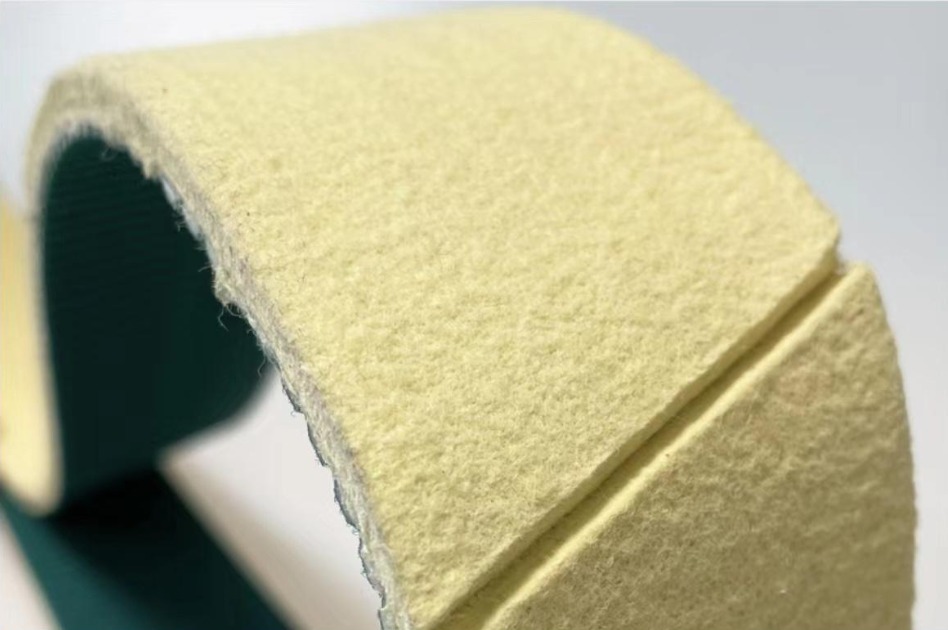

Aramid synchronous belts, known for their exceptional strength, durability, and stability, are widely used in demanding industrial transmission applications. Below is an analysis of the current market landscape and future trends based on available industry insights.

📊 Current Market Overview

- Market Size & Growth: The global aramid fiber market for rubber belts was valued at approximately $227 million in 2024 and is projected to reach $350 million by 2031, growing at a CAGR of 6.9% from 2025 to 2031. China accounts for over 30% of global consumption and is a major production and consumption hub.

- Key Growth Drivers:

- Industrial Automation & Lightweighting: Manufacturing upgrades and automation demand higher efficiency and reliability, driving adoption of high-performance synchronous belts. Aramid belts reduce weight and energy consumption.

- Automotive Industry Shift: New energy vehicles (NEVs) require belts that perform under high torque and temperature fluctuations. Aramid belts support lightweighting and extended battery range.

- Replacement of Traditional Materials: Aramid fibers offer higher strength, lighter weight, and better corrosion resistance compared to steel or polyester, increasing adoption in applications requiring long life and minimal maintenance.

- Competitive Landscape:

- The market is consolidated, dominated by global players like DuPont (Kevlar®), Teijin (Twaron®), Kolon Industries (Heracron®), and China’s Yantai Tayho (Tayho Advanced Materials).

- These suppliers maintain long-term partnerships with major belt manufacturers (e.g., Gates, Continental, Mitsuboshi, Bando), creating high entry barriers.

- Chinese producers, such as Tayho, are expanding capacity (approx. 16k tons each for para- and meta-aramid) and accelerating R&D.

- Regional Markets:

- Asia-Pacific is the largest and fastest-growing market, led by China’s strong manufacturing and automotive sectors.

- North America and Europe are mature markets with steady demand from high-end manufacturing, automotive, and aerospace industries.

- Key Challenges:

- High Cost: Complex production processes make aramid belts more expensive than alternatives, limiting use in cost-sensitive applications.

- Technical Barriers: Achieving uniform dispersion and adhesion of aramid fiber in rubber requires specialized know-how.

- Supply Chain Risks: Dependency on few raw material suppliers creates potential vulnerabilities to price volatility and geopolitical issues.

🔮 Future Trends

- Technology Innovation & Performance Enhancement

- Material Composites & Structural Optimization: Future belts may integrate carbon fiber, polyurethane, or other materials to improve wear resistance, temperature tolerance, and anti-static properties.

- Smart Belts & Condition Monitoring: Belts with embedded sensors could enable real-time monitoring of tension, temperature, and fatigue, supporting predictive maintenance and reducing unplanned downtime.

- Expanding Applications

- New Energy Vehicles (NEVs): Increased use in electric motor drives and auxiliary systems.

- High-End Equipment & Precision Manufacturing: Growing adoption in robotics, semiconductor equipment, and medical devices where precision, cleanliness, and reliability are critical.

- Green Energy & Efficiency: Aramid belts will see more use in wind power and high-efficiency conveying systems due to their lightweight and energy-saving properties.

- Sustainability & Circular Economy

- Increased focus on recyclability, bio-based materials, and environmentally friendly production processes.

- Evolving Regional Dynamics

- China’s role will keep expanding as both a consumer and producer, with local companies advancing in technology and competing globally.

- Cost Optimization & Intensifying Competition

- As technology improves and production scales, costs are expected to decline, enabling broader adoption.

- Competition will emphasize product differentiation, customized solutions, and technical service.

💎 Conclusion

The aramid synchronous belt market is growing steadily, fueled by industrial automation, automotive electrification, and substitution of traditional materials. Future success will depend on innovation, supply chain resilience, customization for key applications, and sustainability.

This analysis provides a high-level overview suitable for industry professionals and decision-makers. For more detailed insights into specific regions or applications, further research is recommended.