Bulletproof vests work by using high-strength, high-modulus fiber layers to absorb projectile energy through:

(1) fiber stretching,

(2) fiber breakage & fibrillation,

(3) yarn & fabric deformation,

(4) non-penetrating backface bulge

(5) projectile deformation.

Most energy is absorbed as fibers rapidly disperse stress waves (sound waves)—faster wave speed means better energy distribution and protection. Learn how advanced fibers enhance ballistic performance!

When a fiber-based ballistic material is struck, the external force causes the fibers to stretch and deform, converting the absorbed impact energy into the work required for fiber deformation. The stress/strain longitudinal wave generated by the impact propagates rapidly through the material—a phenomenon known as the “shock wave” (or acoustic wave).

The speed of sound in the fibers determines how quickly the impact energy disperses, influencing the volume of fibers involved in energy absorption. A higher acoustic velocity in fibers allows for faster energy distribution, engaging more material in the process and ultimately enhancing bulletproof performance.

In bulletproof materials, if the fibers are straight and aligned, the shock wave can travel along the fiber axis over longer distances without reflection, enabling rapid energy dispersion. However, if the fibers are crimped (“S-shaped”) or broken, the bends and fractures reflect the shock wave, reducing the instantaneous energy spread and weakening ballistic protection.

This explains why unidirectional (UD) fiber sheets offer superior bullet resistance compared to traditional woven fabrics—their aligned structure maximizes impact energy absorption and minimizes wave reflection.

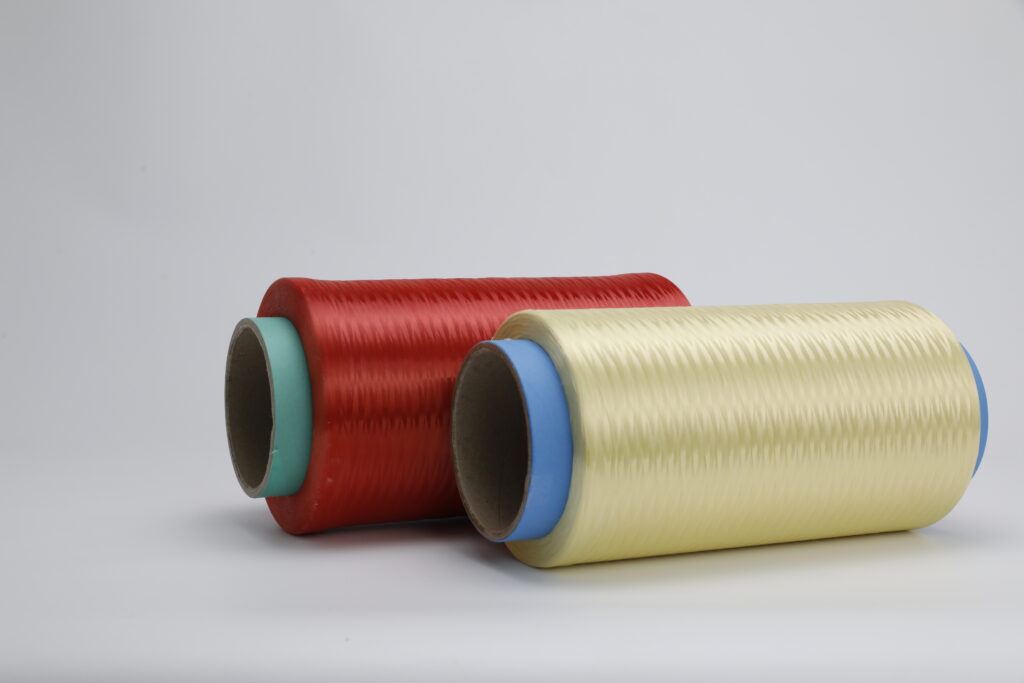

Key Structural Features of Aramid Fibers

Aramid fibers are composed of rigid aromatic rings and amide linkages, forming an extended rod-like molecular structure. This high rigidity, combined with a linear polymer chain arrangement, maximizes packing density, allowing more polymer chains per unit volume—resulting in exceptional strength.

Additionally, the near-straight conformation of these macromolecules minimizes their cross-sectional area while increasing resistance to bond angle deformation and molecular rotation. Their high molecular weight further enhances structural integrity.

Why Aramid Fibers Dominate Military Ballistic Protection

As a critical material for defense applications, aramid fibers meet modern warfare demands. Developed nations like the U.S. and U.K. use aramid in bulletproof vests and helmets, where its lightweight properties enhance troop mobility, rapid response, and combat effectiveness.

The ballistic resistance of aramid fibers stems from:

- Superior thermal stability

- High crystallinity

- Highly oriented structure

- Outstanding tensile performance

Aramid fiber’s high glass transition temperature and exceptional thermal stability ensure structural integrity even under extreme heat generated by ballistic impacts. Its high crystallinity and oriented molecular structure deliver ultra-high modulus, enabling rapid response to axial deformation. Combined with high elasticity and moderate elongation, aramid achieves remarkable toughness, maintaining performance even at fracture points.

Superior Ballistic Protection Mechanics

Para-aramid woven fabrics excel with:

- Ultra-high tensile strength

- Outstanding elastic modulus

- Low density (1.44g/cm³)

These properties enable instantaneous impact energy absorption and dispersion, preventing blunt force trauma. Recognized as the ultimate bulletproof material, aramid outperforms with: - 20% lighter than carbon fiber

- 40% lighter than fiberglass

- 6-7x stronger than steel wire

- Only 20% the weight of steel

Advanced Composite Applications

Aramid fiber composites revolutionize armor systems with:

✔ Negative thermal expansion coefficient

✔ High fracture elongation

✔ Exceptional impact strength

✔ Industry-leading specific modulus

As second-generation composite armor, aramid/resin matrices dominate with:

- Flame resistance (self-extinguishing)

- Solvent/chemical resistance

- Broad operational temperature range

- Unmatched strength-to-weight ratio