Abstract:

Concrete is a widely used construction material due to its high compressive strength and durability. However, its inherent brittleness and low tensile strength often necessitate reinforcement to enhance its structural performance. This study investigates the use of carbon fiber, aramid fiber, and a hybrid of both fibers to reinforce concrete. The experimental results demonstrate significant improvements in the mechanical properties of concrete, particularly in terms of tensile strength, impact resistance, and crack control.

1. Introduction

Concrete is a fundamental material in construction, prized for its compressive strength. However, its low tensile strength and brittleness present challenges that can compromise the integrity and longevity of structures. Fiber reinforcement is a widely recognized method to address these issues, with carbon fiber and aramid fiber being popular choices due to their excellent mechanical properties.

Carbon fiber is known for its high strength-to-weight ratio, stiffness, and resistance to corrosion, making it an ideal candidate for reinforcing concrete. Aramid fiber, commonly known under the brand name Kevlar, offers exceptional impact resistance, toughness, and thermal stability. This study aims to evaluate the effectiveness of carbon fiber, aramid fiber, and a hybrid mix of these fibers in enhancing the mechanical properties of concrete.

2. Experimental Methodology

2.1 Materials and Mix Design

The concrete mix used in this study consisted of standard Portland cement, fine aggregates, and coarse aggregates. To this base mix, varying amounts of carbon fiber, aramid fiber, and a hybrid mix (carbon and aramid fibers combined) were added. The fiber content was adjusted to optimize the balance between workability and performance.

2.2 Preparation and Testing

Concrete specimens were prepared for each type of fiber reinforcement and a control group with no fiber addition. After proper curing, the specimens were subjected to a series of mechanical tests, including:

- Compressive Strength Test: To measure the maximum load-bearing capacity under compressive stress.

- Tensile Strength Test: To evaluate the resistance of concrete to tension, highlighting improvements in ductility.

- Flexural Strength Test: To determine the ability of concrete to resist deformation under load.

- Impact Resistance Test: To assess the toughness of the material and its ability to withstand sudden forces.

- Crack Propagation Analysis: To observe the behavior of cracks in concrete and how fibers influence crack control and distribution.

3. Results and Discussion

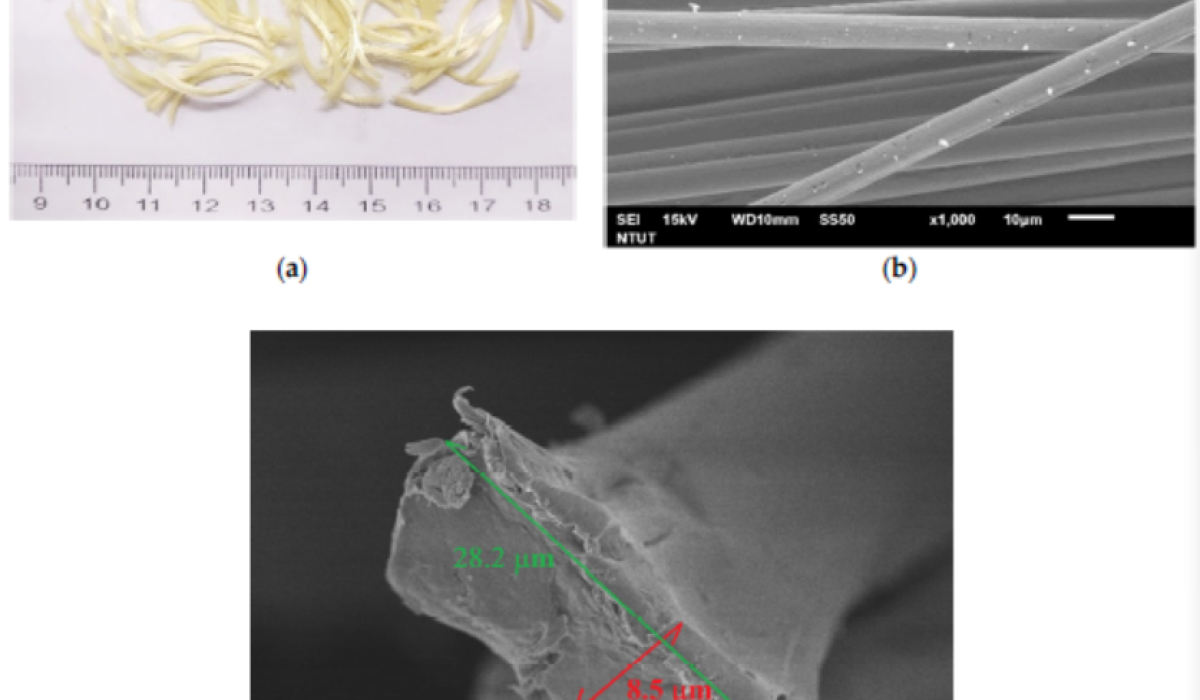

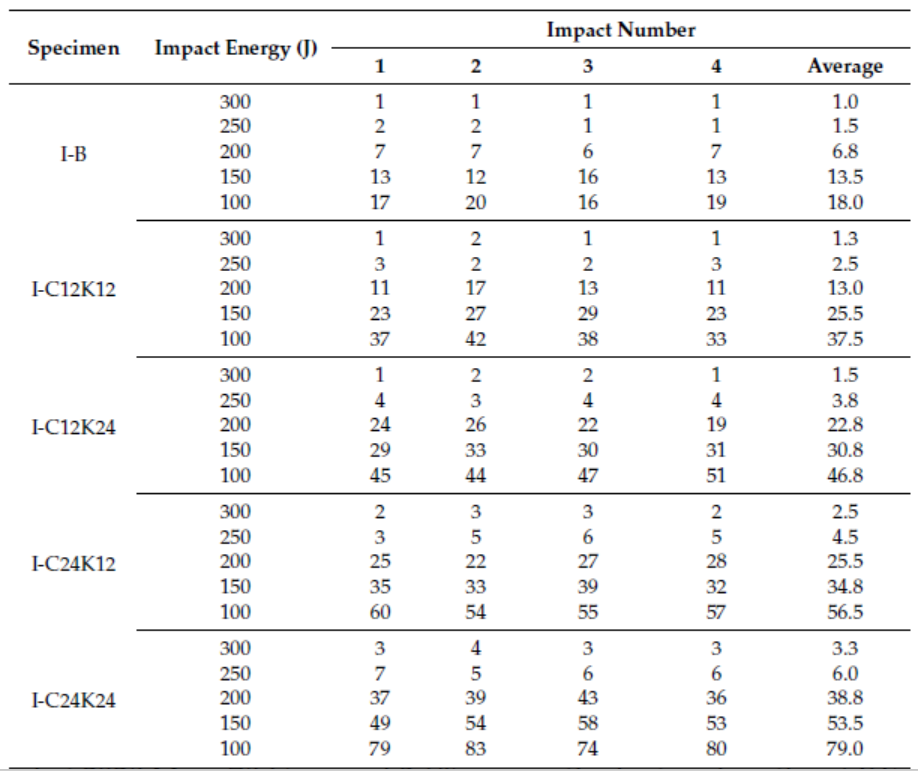

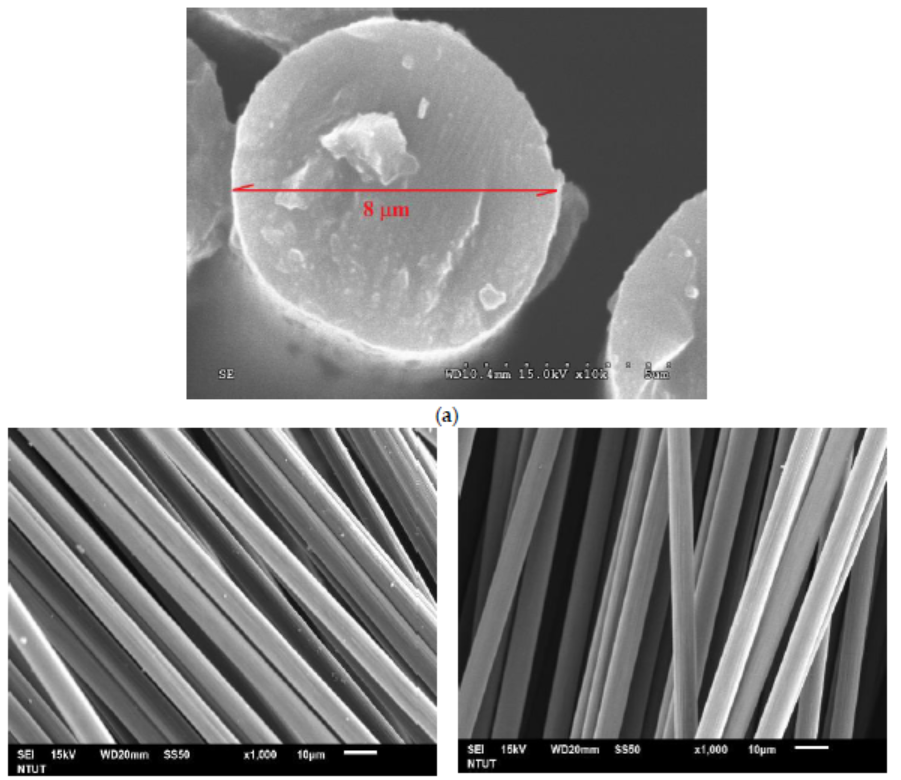

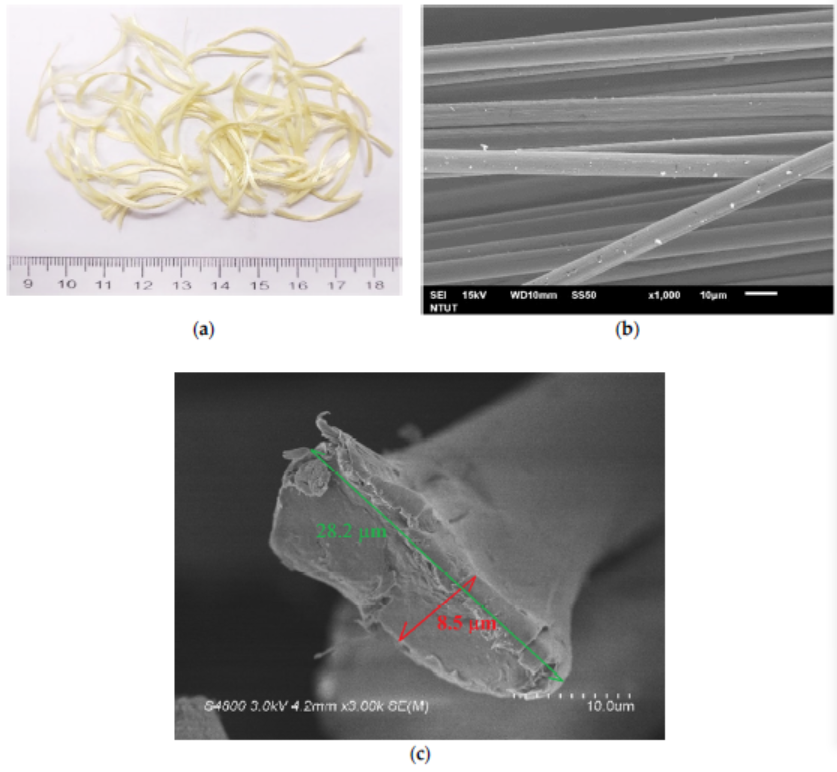

Concrete is a brittle material due to its poor tensile strength; consequently, concrete

tends to crack or peel under an applied external load. Previous studies have investigated the

effect of incorporating fiber into concrete, which can improve its tensile strength. In this study, the

static and dynamic mechanical characteristics of three types of fiber-reinforced concrete (FRC) were

examined: carbon-fiber-reinforced concrete (CFRC); aramid-fiber-reinforced concrete (AFRC); and a

combination of both, known as carbon/Aramid-hybrid-fiber-reinforced concrete (HFRC). This study

created concrete specimens by pneumatically dispersing carbon and Kevlar fibers and mixing them

with cement to comprise 1% of the weight. The mixture was then combined with aggregates and

water to form the concrete specimens. When compared with the benchmark concrete specimens,

it was found that the compressive strength of the CFRC, AFRC, and HFRC specimens increased

by about 19% to 50%, the bending strength increased by about 8% to 32%, and the splitting strength

increased by about 4% to 36%. Specifically, the HFRC made with the 24 mm carbon and aramid

fibers displayed the most significant mechanical strength in a static state. Furthermore, the HFRC

showed superior resistance to impact compared to the benchmark concrete specimens across various

impact energies, with the 24 mm carbon and Aramid fiber HFRC showing the highest resistance. The

inclusion of fibers in the split Hopkinson pressure bar (SHPB) test demonstrated a notable increase in

the maximum strength, particularly in the case of the 12 mm carbon fiber combined with the 24 mm

Aramid fiber in the HFRC specimen.

3.1 Carbon Fiber Reinforced Concrete (CFRC)

The addition of carbon fiber significantly improved the tensile strength and flexural strength of the concrete specimens compared to the control group. The compressive strength showed a marginal increase, while the impact resistance was enhanced considerably. Carbon fiber’s inherent high modulus of elasticity contributed to better crack control, with fewer and narrower cracks observed.

3.2 Aramid Fiber Reinforced Concrete (AFRC)

Aramid fiber reinforcement led to notable improvements in impact resistance and toughness of the concrete. The tensile and flexural strengths were also enhanced but to a lesser extent compared to carbon fiber. The aramid fibers effectively absorbed impact energy, reducing crack initiation and propagation. The thermal stability of aramid fiber also contributed to the overall durability of the concrete under varying environmental conditions.

3.3 Hybrid Carbon-Aramid Fiber Reinforced Concrete (HCFRC)

The hybrid reinforcement of carbon and aramid fibers offered the most balanced enhancement of concrete properties. This combination synergized carbon fibers‘ high tensile and flexural strength with the impact resistance and toughness of aramid fibers. The hybrid fibers provided superior crack control, with minimal crack width and distribution. This mix also showed the best overall performance in impact resistance tests, making it a promising solution for applications requiring high durability and structural integrity.

4. Conclusion

The experimental results indicate that fiber reinforcement significantly enhances the mechanical properties of concrete. Carbon fiber contributes to higher tensile and flexural strength, while aramid fiber improves impact resistance and toughness. The hybrid mix of carbon and aramid fibers combines the advantages of both materials, providing a comprehensive solution for reinforcing concrete structures.

These findings suggest that the selection of fiber type and content should be based on the application’s specific requirements. For projects where high tensile strength and stiffness are crucial, carbon fiber is the preferred choice. Aramid fiber is more suitable for environments with high-impact forces. The hybrid fiber mix is ideal for applications demanding a balance of strength, toughness, and durability. Future research could explore the long-term performance of these fiber-reinforced concretes under real-world conditions and their behavior under different environmental stresses.

Keywords: Carbon fiber, Aramid fiber, Concrete reinforcement, Hybrid fiber, Mechanical properties, Impact resistance, Crack control.