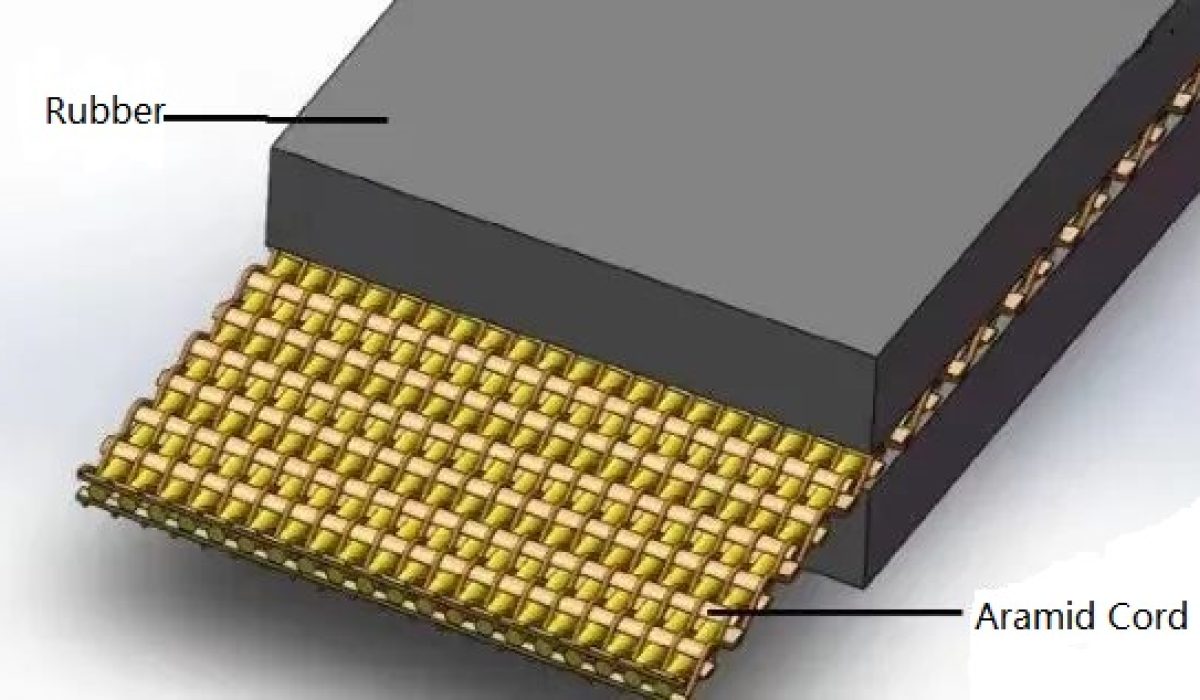

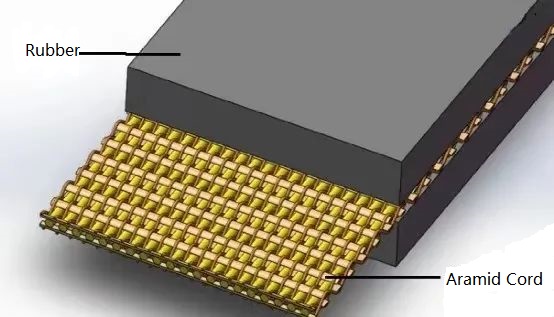

Poly(p-phenylene terephthalamide), commonly known as para-aramid, and poly(m-phenylene isophthalamide), commonly known as meta-aramid, are two types of aramid fibers with distinct molecular structures. They exhibit unique properties that make them suitable for various applications in the civil market. Here, I will focus on the applications of para-aramid in rubber conveyor belts and meta-aramid in firefighting and protective clothing.

- Para-Aramid (对位芳纶) in Rubber Conveyor Belts:Para-aramid fibers, such as Kevlar, Towaron, Vicwa, possess exceptional strength, heat resistance, and resistance to abrasion, making them ideal for use in rubber conveyor belts. The unique combination of properties offered by para-aramid fibers enhances the performance and durability of conveyor belts in demanding industrial environments. Key features include:

- High Tensile Strength: Para-aramid fibers are known for their high tensile strength, providing robust reinforcement to rubber conveyor belts. This ensures that the belts can withstand heavy loads and harsh operating conditions.

- Heat Resistance: Para-aramid fibers can withstand elevated temperatures, making them suitable for applications where heat resistance is crucial, such as in conveying hot materials or operating in environments with high temperatures.

- Abrasion Resistance: The exceptional abrasion resistance of para-aramid fibers contributes to the longevity of conveyor belts, reducing wear and tear in abrasive environments.

- Lightweight: Para-aramid fibers are lightweight, which helps in reducing the overall weight of conveyor belts, improving energy efficiency and ease of handling.

- Meta-Aramid (间位芳纶) in Fire-resistant Protective Clothing:Meta-aramid fibers, like Nomex, are known for their flame-resistant properties, making them suitable for applications in protective clothing, especially in firefighting gear. The key attributes of meta-aramid fibers for this application include:

- Flame Resistance: Meta-aramid fibers do not support combustion and are inherently flame-resistant. This property is crucial for ensuring the safety of individuals working in environments with potential fire hazards.

- Thermal Stability: Meta-aramid fibers retain their properties at high temperatures, providing protection against heat and flames. This makes them ideal for use in firefighting suits where exposure to extreme temperatures is a significant risk.

- Comfort and Flexibility: Protective clothing made with meta-aramid fibers is designed to offer comfort and flexibility, allowing for ease of movement for individuals in challenging situations.

- Chemical Resistance: Meta-aramid fibers also exhibit resistance to certain chemicals, adding an additional layer of protection in scenarios where exposure to hazardous substances is a concern.

In summary, para-aramid and meta-aramid fibers find valuable applications in civil markets, with para-aramid being utilized in reinforcing rubber conveyor belts for industrial purposes, and meta-aramid being employed in the manufacturing of fire-resistant and protective clothing for various professions, particularly in firefighting.